New function of ROBOCUT: Improved cutting accuracy of nozzle open condition New!

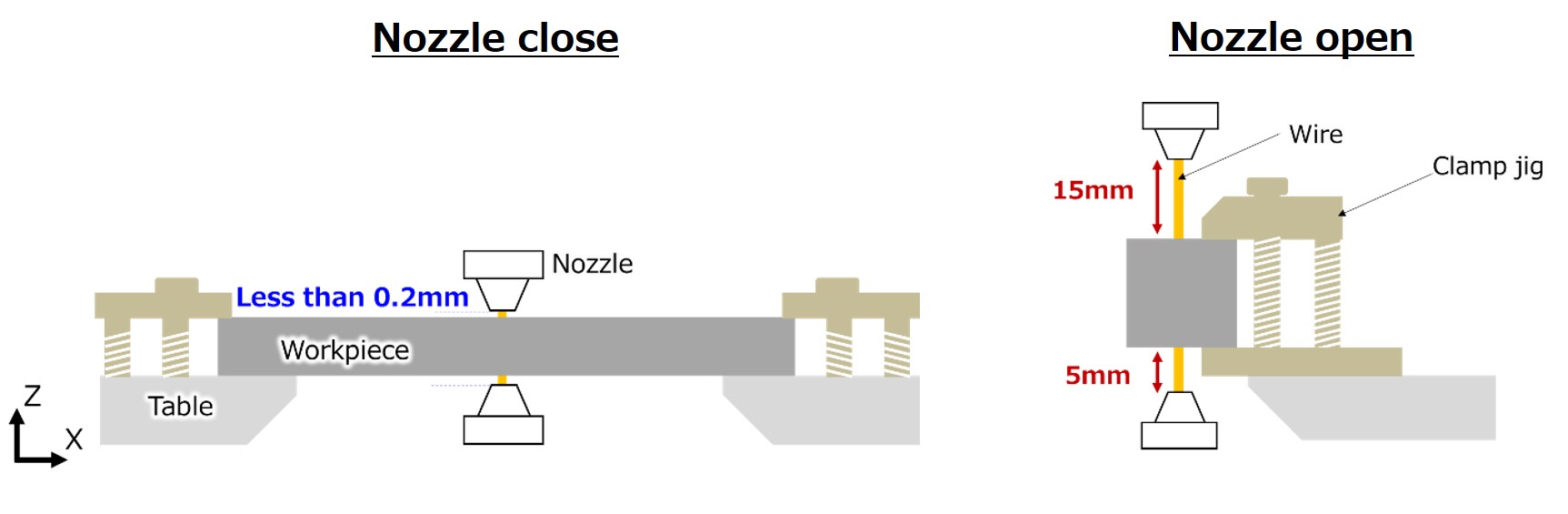

For the requirement from press die market, we have been developing ROBOCUT focusing on both high precision and high speed cutting while the nozzle is close, that is, the nozzle can be positioned closer to the workpiece.

On the other hand, we have received lots of demands of high precision cutting from injection mold market, in which the nozzle cannot be positioned closer to the workpiece because of some restrictions such as their cutting shapes, interference of clamp jigs, and so on.

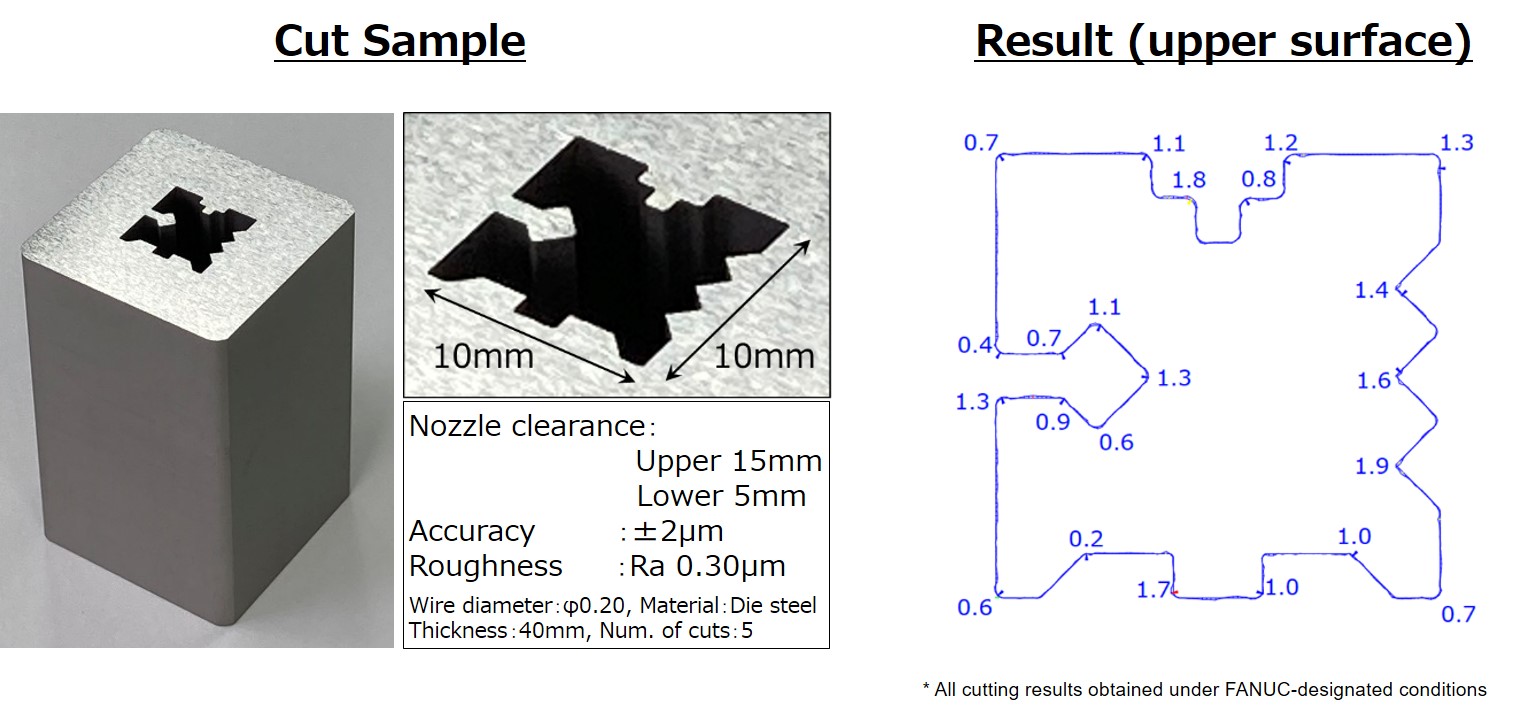

To meet the needs from such markets, we improved the discharge control named iPulse3 so that the high precision cutting could be achieved even while the nozzle is open condition. Further, those EDMs are standard installed on the machine, therefore, the high precision cutting will be provided without adjusting complex discharge parameters. We believe these improvements of nozzle open/close cutting will help high precision cutting in various markets.

We will keep our effort to capture market needs and respond as soon as possible.

(June 2023)