Use Case 3

Demand

Want to lower the costs associated with test cuts.

-

Reducing consumption of workpieces, tools, and cutting fluids to zero. No need to occupy machines, leading to increased operational efficiency.

Digital test cutting suppresses the consumption of workpiece, tools, cutting fluids, and the energy usage of machine tools. By not occupying machine tools, factory operating rates improve. Moreover, enabling remote test cuts allows you to reduce labor hours spent on travel.

Three Highlights

-

01

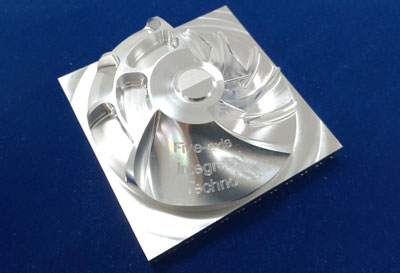

Eliminate consumption of workpieces, tools, and cutting fluids with digital twin test cuts

By performing test cuts digitally using digital twins, it becomes possible to eliminate the consumption of workpieces, tools, cutting fluids, and the entire electricity costs of machine tools that were previously necessary for test cuts.

-

02

By going digital, you can increase operating rates without using actual machine tools.

By performing test cuts digitally, you don't need to occupy machine tools for test cutting, allowing you to use them for production. This contributes to improving operating rates and shortening delivery times.

-

03

Since test cuts can be performed on a PC, movement labor is also reduced.

Even without having the machine tools in front of you, test cuts can be conducted from an office within the factory or from a remote location away from the plant. Therefore, it is possible to reduce the labor time required to move to the location where the machine tools are installed.