Use Case 2

Demand

Want to reduce the time required for test cutting

-

With setup-free and up to 100 times faster simulations, a significant reduction in time can be achieved

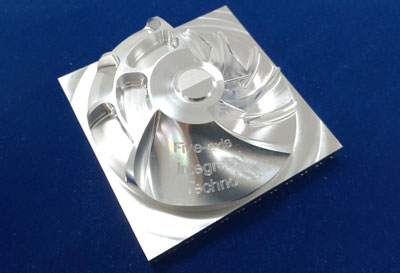

By performing test cutting digitally, it is possible to greatly reduce the time required for test cutting. There is no need for setup of tools and equipment, and with up to 100 times faster simulations, a significant reduction in time can be achieved. Additionally, making changes to various conditions that can affect the machining results is easy when done digitally

Three Highlights

-

01

Up to 100 times faster high-speed simulation

The ability to perform high-speed simulations digitally, up to 100 times faster, eliminates the need for long waiting times until the machining is complete. As a result, it significantly reduces the time required for test cuts.

-

02

If you use a digital twin, you can reduce work time by eliminating the need for setup and preparation

By performing test cutting with a digital twin, it is possible to significantly reduce work time by eliminating the need for setup and actual machining of workpieces, tools, and fixtures. High-speed simulations on the digital platform are conducted using CNC GUIDE 2, and work evaluation on the digital platform is performed through Surface Estimation. By using the Smart Digital Twin Manager, you can seamlessly conduct simulations and work evaluations on the digital platform

-

03

Efficient test cutting through digital trial and error

By considering various information that affects the machining results, you can conduct test cutting digitally. Therefore, even if the results of the test cutting are not as expected, you can easily and seamlessly perform trial and error by modifying this information digitally

CNC GUIDE 2

CNC GUIDE 2