Use Case 1

Demand

Want to resolve machined surface defects

-

Identifying the cause and efficiently resolve the issue using simulation on Surface Estimation

3 types of simulations assist in identifying the causes of machined surface defects. This leads to resolution of the issue with minimal effort and time. In addition, highlighting information that may affect surface quality, such as tool acceleration and tool path, on the digitally machined surface assists in improvement work. If it is determined that there are issues with the machining program, you can optimize the program accordingly.

Three Highlights

-

01

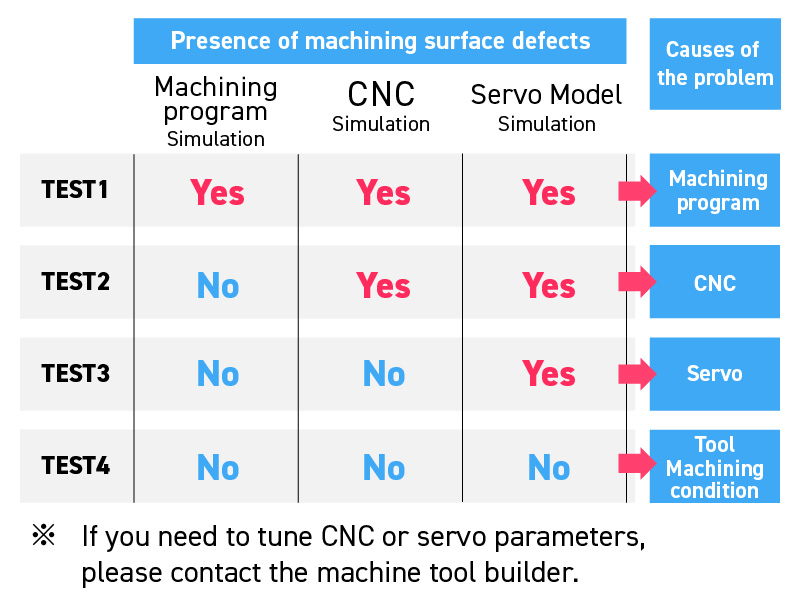

With the three simulation results, it is easy to identify the specific causes of the machined defects.

By changing the evaluation methods and machining conditions and conducting simulations, it is possible to identify the causes of machined defects based on the differences in the simulation results. By performing Surface Estimation using the three simulations: machining program, CNC, and Servo Model, it becomes easy to pinpoint where the cause of the machined defects lies.

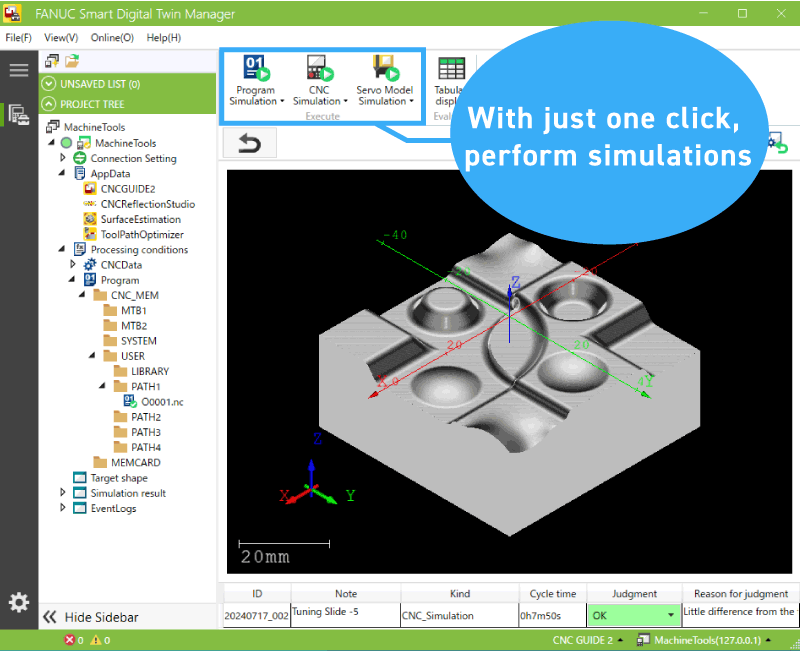

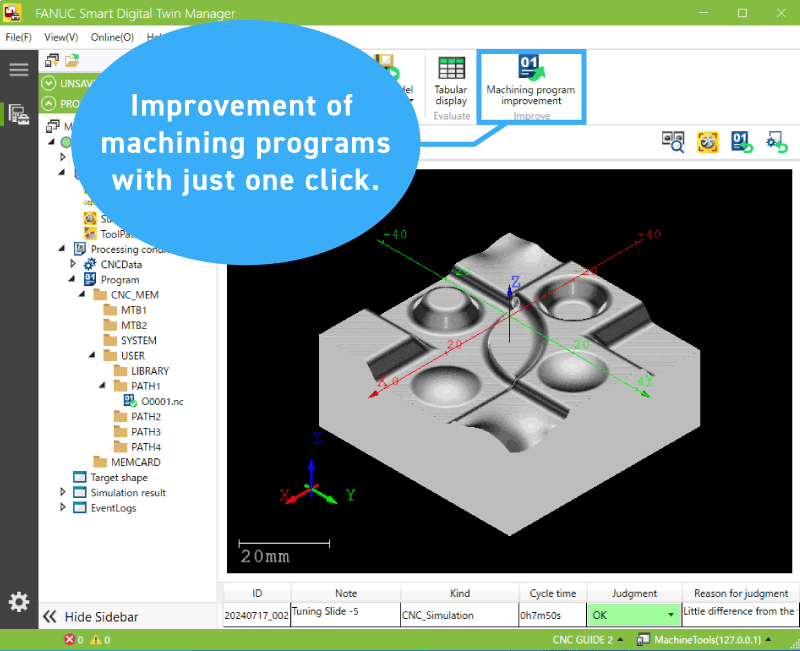

With the use of Smart Digital Twin Manager, you can easily perform three simulations with just one click of a button.

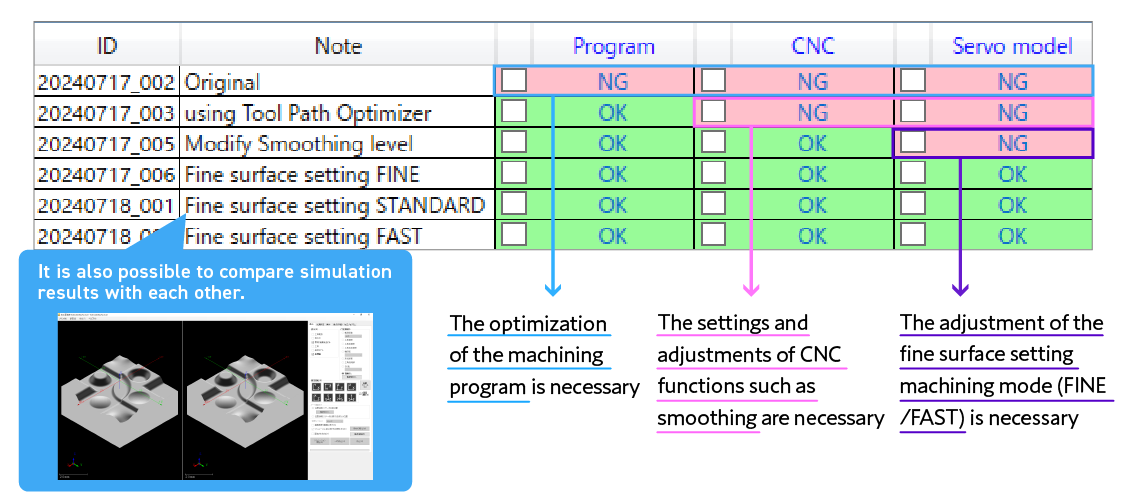

You can easily check, compare, and manage simulation results, which can be helpful in identifying the causes of machined defects.

-

02

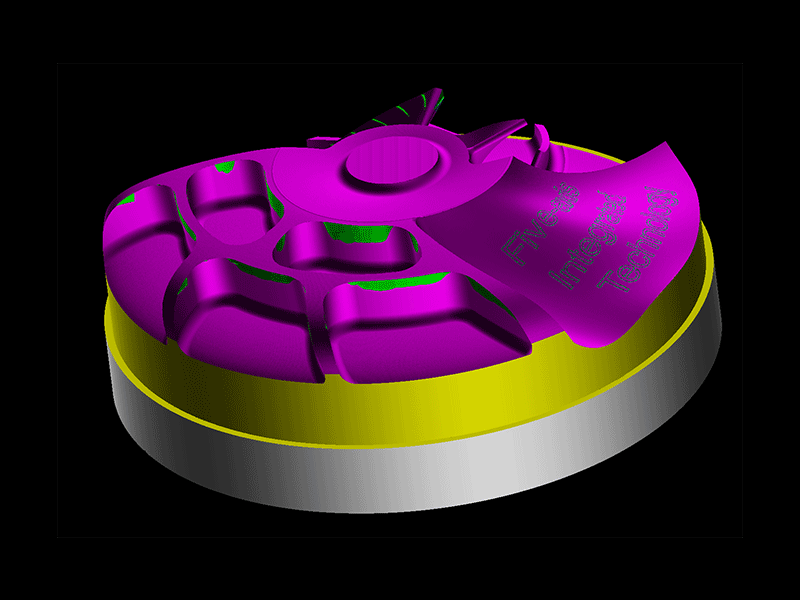

By digitally displaying information that affects surface quality, it becomes easier to identify the causes of machined defects.

By displaying information that affects surface quality, such as tool speed, tool acceleration, and tool path, as additional information on the machined surface, it assists in improving the surface quality. It also has the functionality to color-code the machined areas by tool and identify the machining program blocks corresponding to the tool path, making it easier to identify and analyze the causes of machined defects

-

03

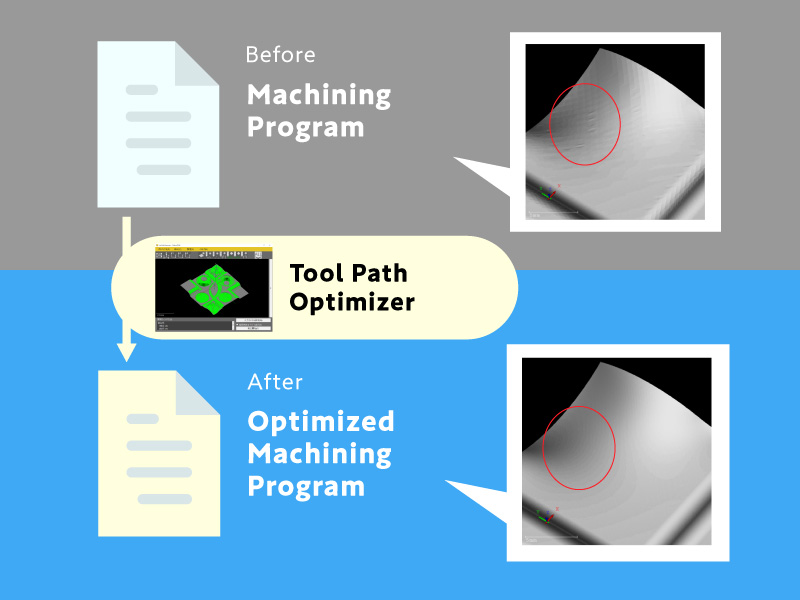

Optimizing a problematic machining program

If there are issues with the micro-line instructions in a machining program, it is possible to easily optimize the program using a Tool Path Optimizer. The Tool Path Optimizer is a computer software that optimizes the micro-line instructions in the machining program for higher precision and quality. With the optimized machining program, you can perform a re-simulation and immediately see the improvement effects digitally

With the use of Smart Digital Twin Manager, you can seamlessly improve machining programs with just one click using the Tool Path Optimizer

Smart Digital Twin Manager

Smart Digital Twin Manager