Innovate machining,

by trying in digital

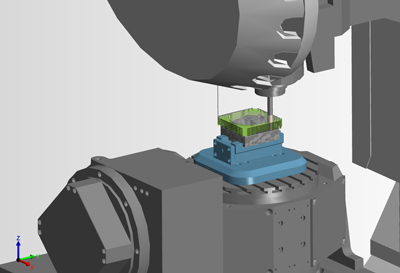

before actual cuttingFANUC Smart Digital Twin® is a collective name of computer software that realizes Digital Twin of FANUC CNC.

Servo Model generated based on FANUC's accumulated CNC technologies realizes the same level of validation as real machining digitally.

It performs high-speed and high-precision digital validation to minimize actual trial cutting, which realizes a smarter production workspace.

- CONCEPT

Cut with Confidence

Transform the Workflow

Three benefits of FANUC Smart Digital Twin®

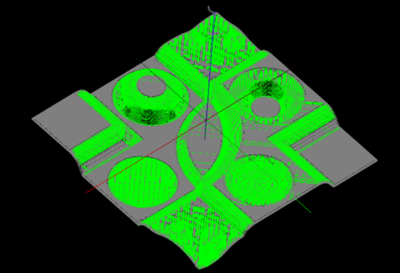

By knowing Machine Motion

Accurate machine simulation is realized by Servo Model which is reflecting mechanical characteristics. It leads to reducing the setup time on site.

By knowing Cycle Time

Precise cycle time can be estimated. It leads to efficient optimization of process configuration.

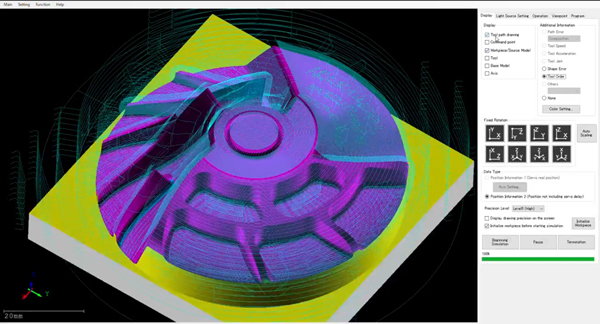

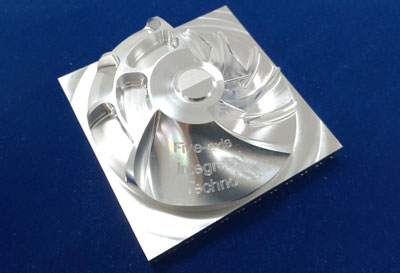

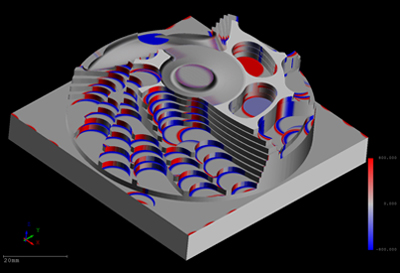

By knowing Machined Surface Quality

Surface quality significantly close to real machining can be validated in advance. It leads to minimizing waste and loss due to actual trial cutting.

Use Case

Use Case 1

For identifying the causes of machined surface defects efficiently

Use Case 2

For saving time on test cutting

Use Case 3

For reducing costs related to test cutting

Product List

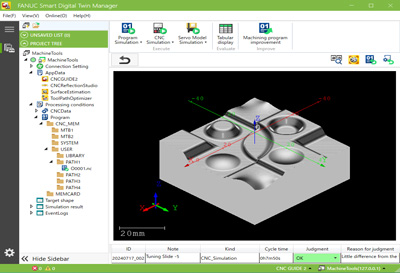

Smart Digital Twin Manager

Integrated Environment of FANUC Smart Digital Twin®

CNC GUIDE 2

Fast and accurate CNC simulator

Surface Estimation

Tool for checking machined surface quality

Tool Path Optimizer

Machining program optimization tool

CNC Reflection Studio

Tool to verify accurate machine operation