FANUC Robots will contribute your productivity-up by “High Reliability”, “High Efficiency” and “High Flexibility”.

FANUC Robots will provide your factories with a wide range of advantages such as Increased Productivity, Improved Work Reliability, Higher Product Quality and Reduced Costs.

FANUC Robots will provide “reliable”, “predictable” and “easy to repair” functions to realize a higher productivity of your factories.

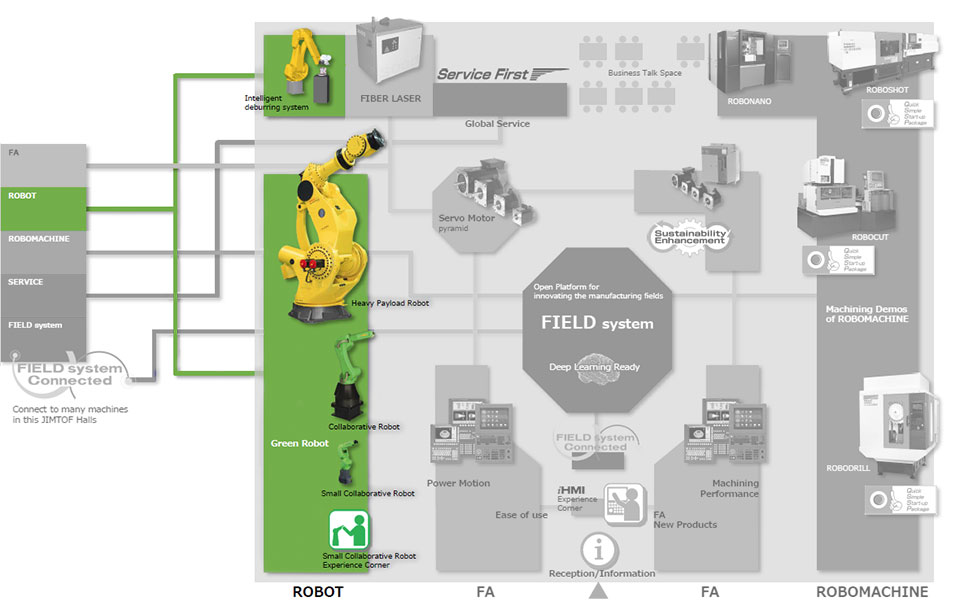

CR-35iA is a first 35kg payload collaborative robot with safety certification. In addition to this robot, FANUC adds new 3 types of small collaborative robots line-up. These Collaborative robot can work in cooperation with a human operator and bring production efficiency and save labor in your factories.

The Bin Picking Robot equipped with a vision sensor automates the picking process of randomly piled parts in a bin. The Bin Picking Robot enables unmanned part handling in your factories.

You can experience Green Collaborative Robot without safety fence exhaustively.

You can actually touch and try 35kg payload collaborative robot with hand guidance, and 3 types of small collaborative robots.

Robot relocation on the trolley is possible.

You cannot miss the demonstration which will liberate human operator from treadmill of parts provide work.

3D Model Matching Function recognizes complex shaped parts piled in the container.

High speed take-out and pile sheet panel parts from random flow from the conveyer checking and detecting with vision sensor. Excellent Genkotsu 2 aligns and sorts 120 units per min.

You can experience with the powerful transportation work of Platen to the injection molding machine by World largest 2.3t super heavy payload robot right in front of you. Don't miss the super heavy payload Robots precise fine positioning work with vision sensor.

M-20iB; a full covered ROBOT with enclosed construction whose cables and motors are not exposed, demonstrates automatic deburring. You can check the efficient casting deburring work in cooperation with motion path generation by Vision sensor and high-quality deburring by Force sensor.

“From Hand selection to System design”, courteous specialized skilled staff will answer to you. Moreover, consulting professional staff conducts Robot simulation for each customer's individual project. Please drop in and see us.