FANUC Open Platform

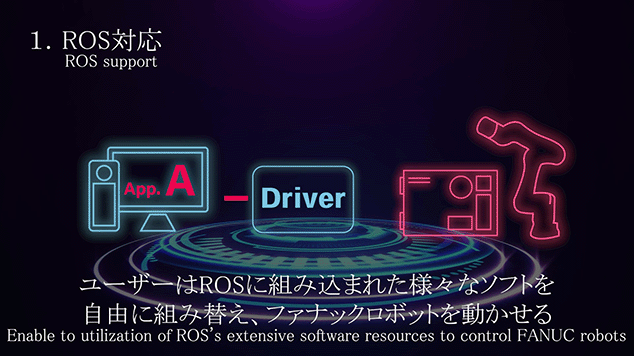

1. ROS 2 Support

FANUC develops the official ROS 2 driver, which serves as the core for robot operation, and publishes it on GitHub. This enables users worldwide to freely reconfigure software and control FANUC robots from a PC through the open-source ROS 2 platform. In particular, FANUC’s ROS 2 driver supports industry-leading ultra-fast communication at 1 ms, enabling real-time control.

Global Release of ROS 2 Driver

ROS 2 is the next-generation robotics development framework, enhanced for real-time performance and security. FANUC has published its ROS2 driver on GitHub, one of the world’s largest platforms. This allows developers worldwide to freely leverage a rich library of shared resources—such as trajectory planning, image recognition, and AI software—and easily integrate them into their systems. Official support is also provided on GitHub, strongly accelerating the adoption of physical AI in real-world applications.

Flexible Program Reconfiguration

A key feature of ROS 2 is the ability to combine diverse software modules published by developers around the globe to suit specific applications. Through Ethernet communication, FANUC robots can be connected to software for simulation, image recognition, sensor control, and AI applications. Existing advanced algorithm software can be downloaded and tested immediately, enabling both shorter development cycles and flexible system construction.

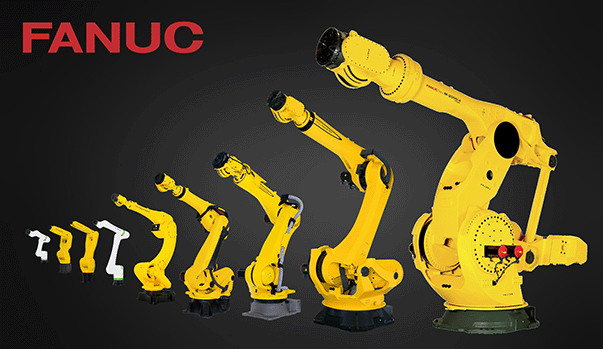

Industry’s Largest Robot Lineup and Ultra-Fast 1 ms Communication

FANUC’s ROS 2 support covers an exceptionally wide range of robots—from the collaborative CRX series to small models with 3 kg payloads and ultra-large models up to 2,300 kg. No other robot manufacturer offers such diversity under a single platform. Furthermore, FANUC’s ROS 2 driver supports industry-leading ultra-fast communication at 1 ms. Combining FANUC’s highly reliable robots with the latest ROS 2 environment delivers optimal robotic systems for everything from small-scale experiments to large-scale production lines, enabling real-time robot control.

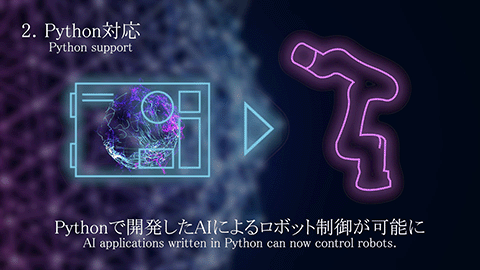

2. Python Support

FANUC’s robot controllers can now execute Python programs directly, without the need for a PC. This enables robot control using AI developed with Python, a language widely used in AI development.

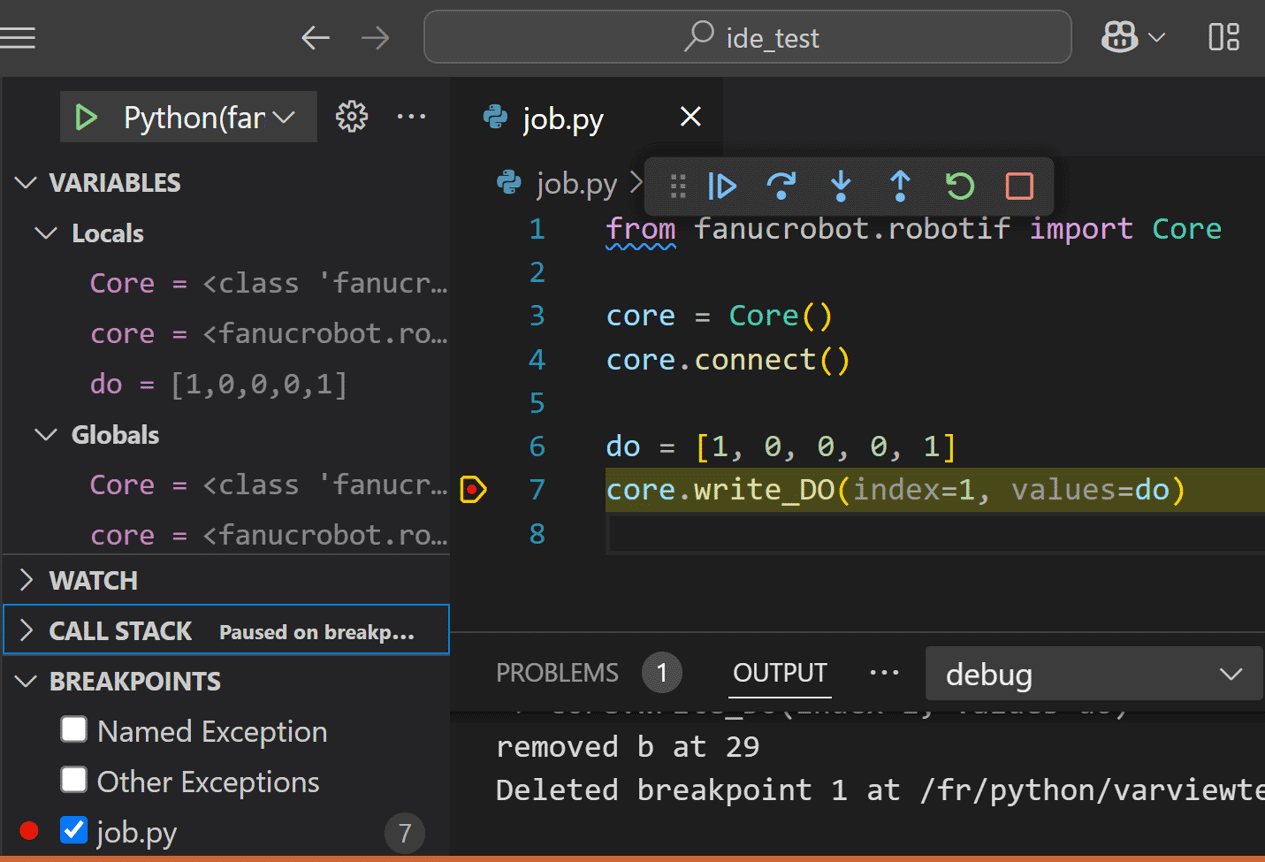

Run Python on the Controller

The globally popular programming language Python can now be executed directly on the robot controller R-50iA. This robot control enables seamless integration of rich open-source libraries—such as those for statistical processing, data analysis, and image processing—into robot control. The development environment supports VS Code (Visual Studio Code)****, allowing efficient program development with advanced remote debugging features such as step execution, breakpoints, and variable views.

Easy to Use with Dedicated Libraries

FANUC provides dedicated Python libraries to simplify robot control. Using these libraries, developers can intuitively access various robot data from Python, such as I/O (signal input/output) and register values (variable settings). Furthermore, by combining the optional Remote Motion Interface, robots can be commanded to move directly from Python. Python programs created in this way can also be called from conventional TP programs, enabling seamless integration of FANUC robots with the latest technologies.

3. Stream Motion Implementation

FANUC has developed and implemented the Stream Motion feature, a high-speed position command communication function, in its robots. This enables the execution of motion commands sent from a PC at an industry-leading ultra-fast communication speed of 1 ms, allowing real-time robot control through robot path generation software.

Industry-Leading Ultra-Fast 1 ms Communication

FANUC’s high-speed position command communication feature supports platform-independent external command input and achieves an industry-leading ultra-fast communication cycle of 1 ms. This exceptional speed ensures that commands from PCs or external devices are transmitted to robots without delay. It provides an optimal development environment for companies that want to develop proprietary software in a closed, secure setting while maintaining confidentiality.

Real-Time Robot Control

Control at an extremely short cycle of 1 ms enables precise, real-time AI-based operations. For example, AI robots can perform complex assembly tasks while sensing cable tension in real time, or instantly optimize trajectories based on human presence and surrounding conditions. This strongly accelerates the introduction of advanced physical AI into production environments. By combining cutting-edge digital technology with FANUC’s proven reliability, we deliver next-generation automation.

* ROS is a trademark of the Open Source Robotics Foundation.

** Python is a registered trademark of the Python Software Foundation.

*** GitHub is a registered trademark of GitHub, Inc.

**** Visual Studio Code and VSCode are trademarks of Microsoft Corporation.