FIELD system Basic Package

Updates

FIELD system Basic Package, which went on sale in March 2023, has been regularly updated with new features.Here are some of the most recently added features.

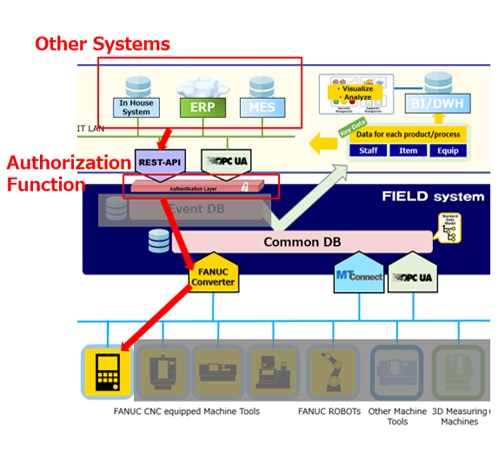

FIELD system Basic Package v3.2 additional functions (Released in September 2025)

- Enhanced user authentication functionality

- User accounts are now integrated with LDAP and Kerberos authentication

- Users can remain logged in even after closing their browser, simplifying the process of re-login

FIELD system Basic Package v3.1 additional functions (Released in September 2024 and April 2025)

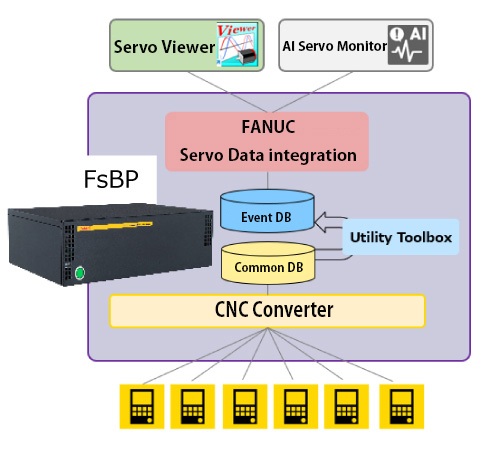

1. Added servo data integration functionality:

A servo data supply platform for AI Servo Monitor and Servo Viewer.

Features

- Collect FANUC servo data with the FIELD system Basic Package and provide it to our AI Servo Monitor and Servo Viewer applications.

2. Added CNC program transfer and macro variable APIs:

Also provided a file transfer API to CNC and an API to read and write CNC macro variables.

Features

- Transfer of CNC programs from FANUC CNC to a host system.

- Backup and restore of FANUC CNC parameters, macro variables, etc.

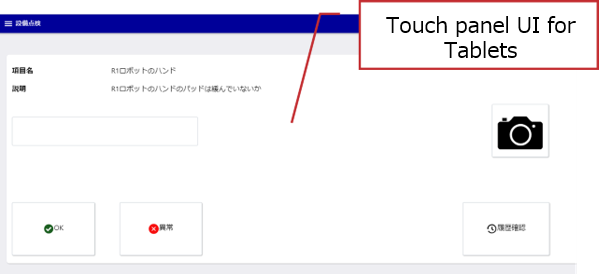

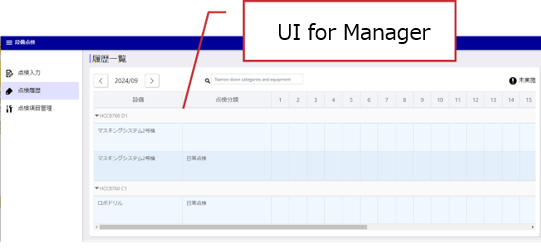

3. Added machines inspection function:

Provided an application for entering and managing machine inspection records.

Features

- Enter and manage machines inspection records by type. Supports inspection of peripheral machine as well.

- UI (tablet and touch panel) for easy on-factory entry.

- Manages inspection result approvals and history.

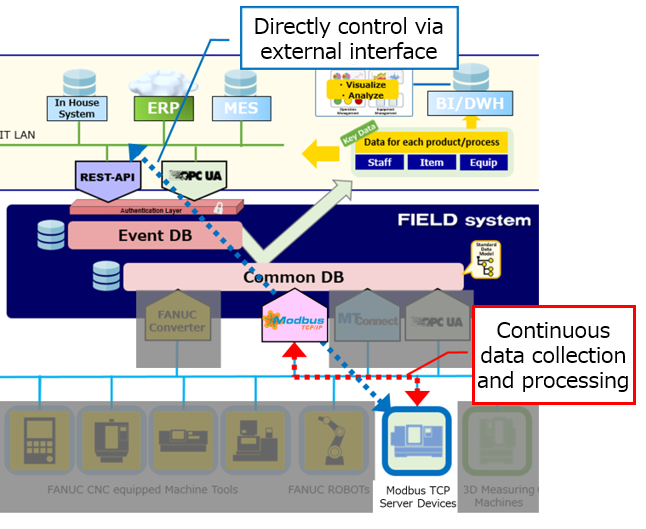

4. Modbus TCP Support:

Connect to Modbus TCP Server (Slave) Devices

Features

- Continuously collect data from Modbus TCP-compatible devices

- Collected data is recorded and aggregated chronologically and made available externally

- Directly control Modbus TCP-compatible devices via an external interface

- Read and write to any address from an MES using OPC UA

- Read and write to any address from an internal system using HTTPS

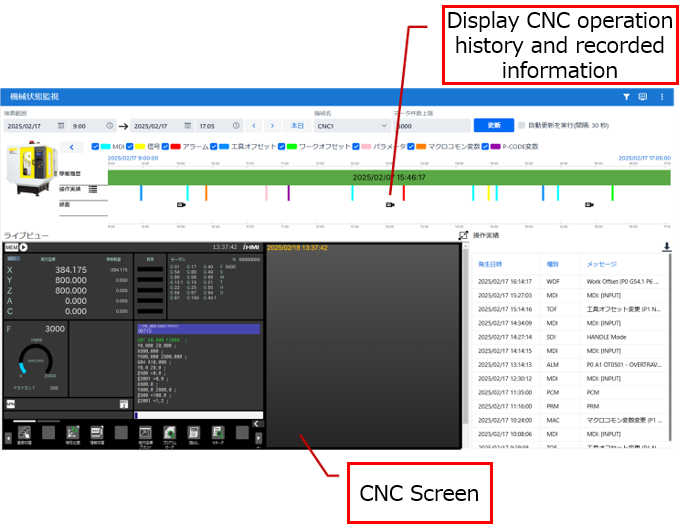

5. Machine Condition Monitoring (Visual Assist) Integration:

Integrates with the FANUC CNC optional Machine Condition Monitoring (Visual Assist) feature, enabling live view, operation history, and recording playback on the Factory Visualizer screen.

Features

- Improve monitoring accuracy by centrally managing the status of multiple machines with Factory Visualizer.

- Utilize data collected by the Machine Condition Monitoring (Visual Assist) feature externally using the FsBP API.

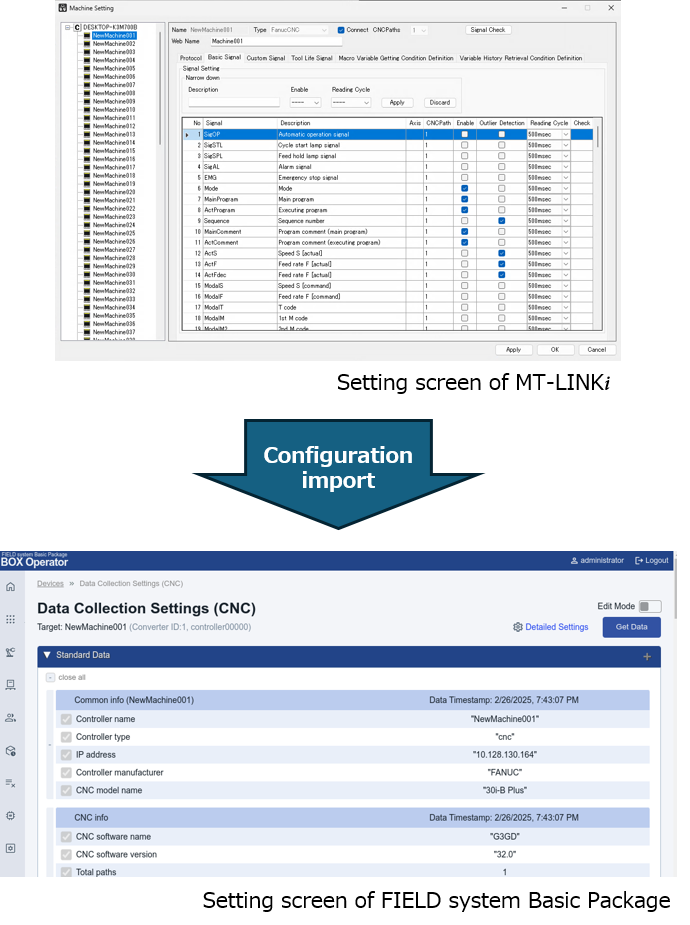

6. MT-LINKi Settings Import

Added a function to import MT-LINKi CNC and robot settings.

Features

- Backup settings files from MT-LINKi can be imported into FIELD system Basic Package for easy configuration migration.

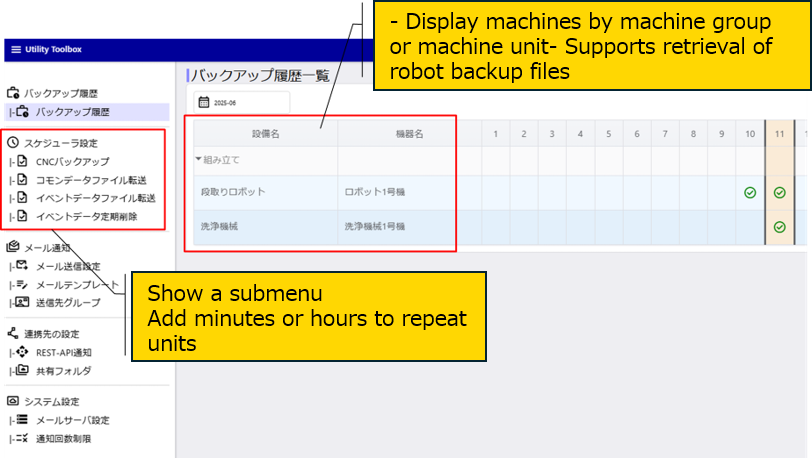

7. Utility Toolbox

Provides CNC and robot backup scheduling functionality Backup history display

Features

- Display backup status by machine

- Easier robot backup file retrieval

- Improved scheduler configuration

FIELD system Basic Package v3.0 additional functions (Released in March 2024)

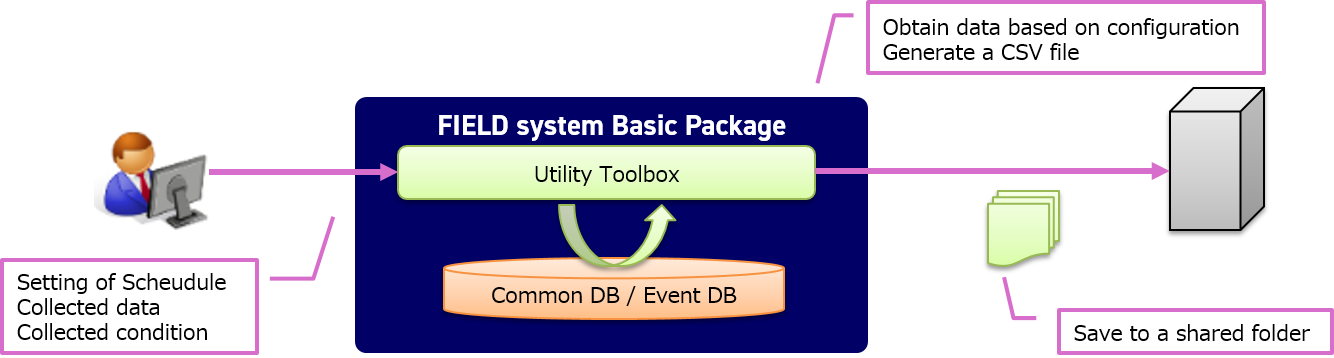

1. Added CSV file data integration function:

This function saves data from the two FIELD system Basic Package databases (common data and event data) as CSV files in a shared folder on the network.

Features

- This applies to data from the common database and event database.

- Can be used in conjunction with the scheduling function for batch processing.

- Save files directly to a shared folder on the same network.

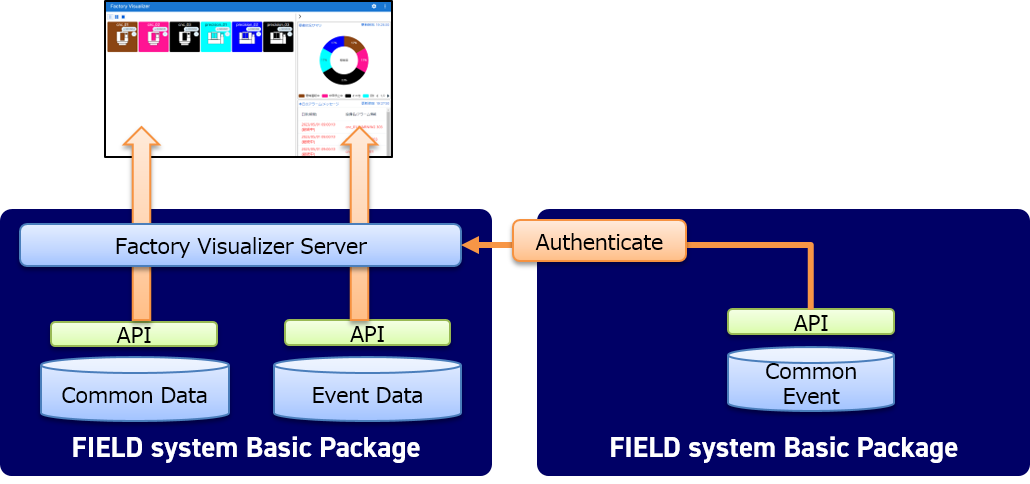

2. Connecting to Other Boxes (Up to 100 Connections)

Can specify the API of another box (FsBP) as a data source for Factory Visualizer.

Can set up data references for other boxes on the Factory Visualizer screen.