FIELD system Basic Package

MT-LINKi integration and migration

Support for cooperate with MT-LINKi and migration to FIELD system Basic Package

FIELD system Basic Package, the successor to MT-LINKi, retains the functionality of MT-LINKi while providing more powerful support for improving the operation of on-factory machine. It also offers features such as connection to other companies' PLCs, backup, restore, and transfer of CNC programs, reading and writing macro variables, and easy utilization of data collected from machine.

Development of MT-LINKi has already ended, but operation and maintenance support continues.

Going forward, we recommend considering using FIELD system Basic Package, which allows you to easily connect to various machine in your factory and immediately begin visualizing and improving the operation of on-factory machine.

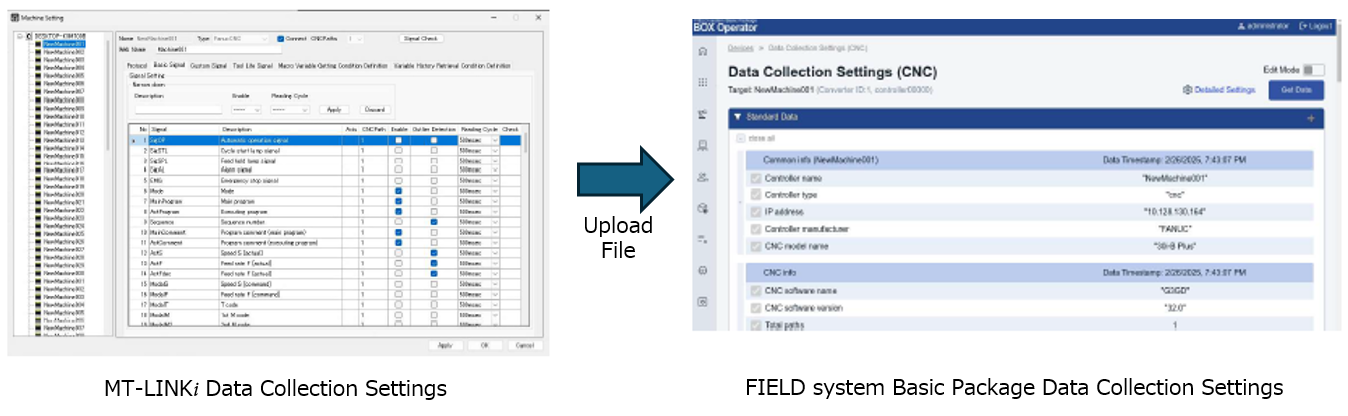

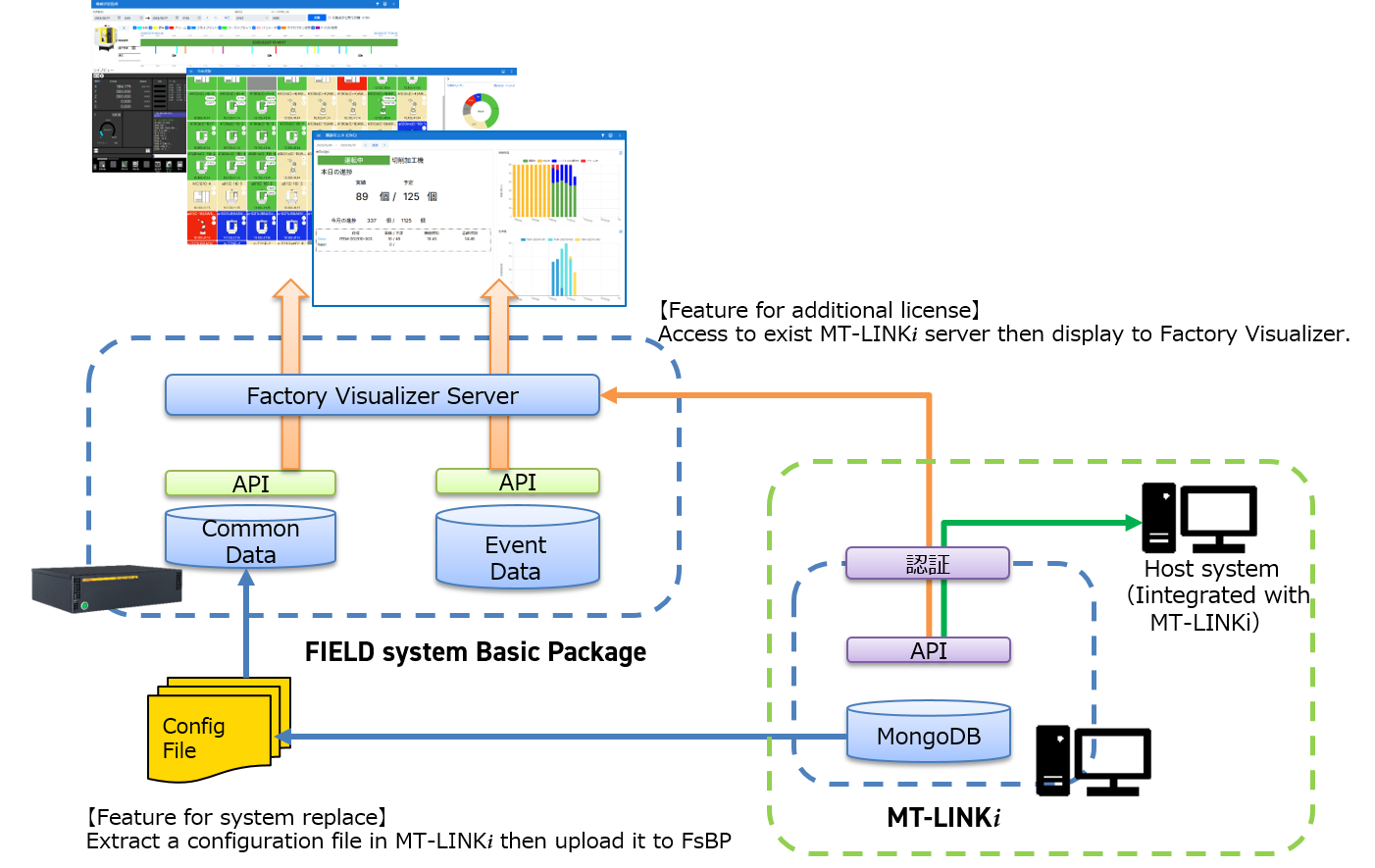

To facilitate migration from MT-LINKi to FIELD system Basic Package, you can use data collected by MT-LINKi in FIELD system Basic Package and migrate MT-LINKi data collection settings to FIELD system Basic Package.

| Comparison | FIELD system Basic Package | MT-LINKi |

|---|---|---|

| Purpose of product | Reduce machine downtime, improve machine utilization rates, and increase production capacity. Preventive machine maintenance, machine maintenance management and external use of machine data. |

Reduce machine downtime, improve machine utilization rates, and increase production capacity. Preventive machine maintenance. |

| Product composition | Software embedded hardware or Virtual Machine (VM) | Windows application |

| Sales product | One-time hardware purchase, annual software usage fee, maintenance fee | One-time software purchase |

| Main features | Overall and individual monitoring of machine such as machine tools and robots, operating status collection, machine signal monitoring email notification when machine abnormalities occur CNC program backup, restore, and transfer CNC macro variable reading and writing Data output to external systems and applications |

Overall and individual monitoring of machine such as machine tools and robots. Operating status collection, machine signal monitoring Email notification when machine abnormalities occur CNC program backup and restore |

| Examples of connectable devices | FANUC CNCs, robots, robomachines, MTConnect or OPC UA compatible CNCs from other companies, etc. Support UA4MT/umati and EUROMAP 77/83 format machine supports Modbus/TCP |

FANUC CNCs, robots, robomachines, MTConnect or OPC UA compatible CNCs from other companies, etc. |

| Number of connectable devices | Maximum 50 devices (Hardware version), Maximum 100 devices (VM version) | Maximum 50 devices |

| Supported output format | CSV file output, REST-API (HTTP/HTTPs compatible) OPC UA(MachineTool Basic Server Profile of UA4MT/umati compatible) |

CSV file output, REST-API (HTTP compatible) |

| Feature expansions Vulnerability response |

Regular or occasional version upgrades are provided in exchange for an annual software usage fee. | Feature development and support for the new OS have been completed, and only maintenance support is ongoing. |

Integration of FIELD system Basic Package and MT-LINKi

Migrating from MT-LINKi to FIELD system Basic Package

By importing MT-LINKi settings into FIELD system Basic Package, you can easily continue data collection and take advantage of new features.