IoT New Functions: Features and New Functions of FIELD system Basic Package

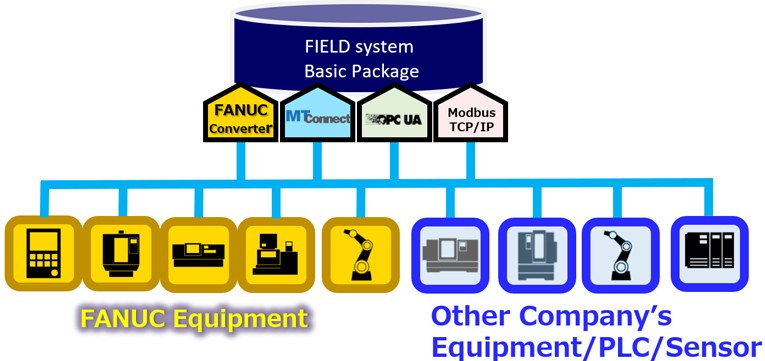

FIELD system Basic Package was launched in 2023 as a data platform that continuously supports improvements in operation, and has received much praise. Functions have been added so that various equipment in customers’ factories can be connected, and enhancements have been made to better interoperate with other FANUC products.

Features of FIELD system Basic Package

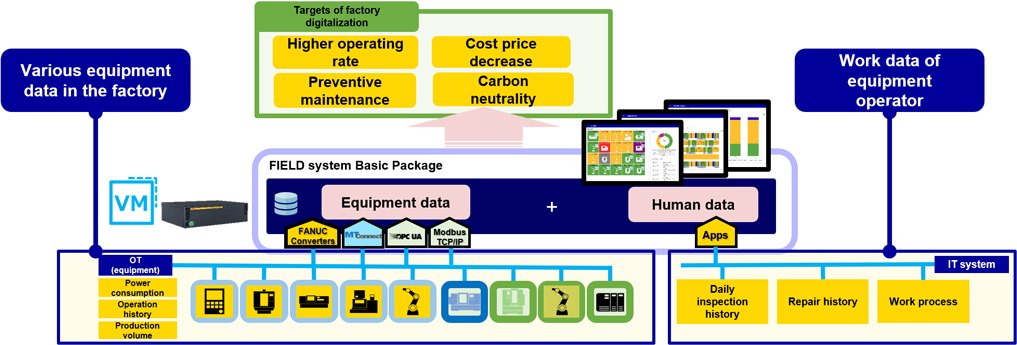

Improving operation in manufacturing sites involves processes for gathering data from equipment, visualization, analysis, and optimization. Due to this, a data platform that serves as a base for connecting different equipment and being the center for data collection plays a pivotal role.

FIELD system Basic Package is such a data platform. It can collect data from various equipment and analyze the data to improve productivity, as well as implement preventive maintenance, contributing to the formation of a smart factory.

FIELD system Basic Package collects the work data of various factory equipment and equipment operators. By connecting IT to OT (operational technology), the goal of digitalizing a factory is achieved.

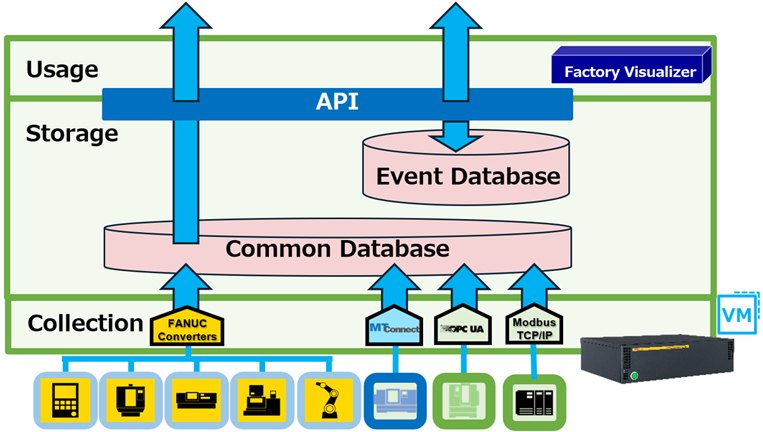

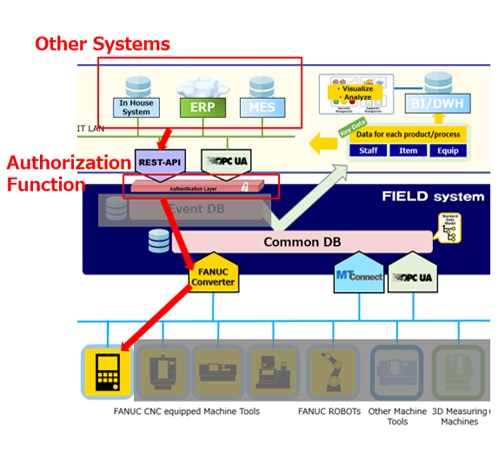

By separating the processes of collecting, storing, and using data, the system ensures that collected data can be shared openly and securely with other systems.

Data Collection

Collects data via Ethernet from various equipment in the factory.

Data Storage

Has two databases.

Common Database:

Standardizes, organizes, and stores data of various factory equipment.

Event Database:

Customizes collected data. Data extracted from the Common Database and external data can be freely stored (data, for example, of people, things, and equipment).

Data Usage

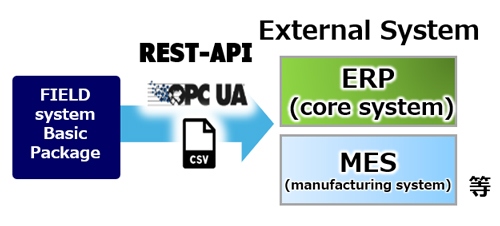

Coordination with External Systems

Data can be used externally by utilizing OPC UA, REST-API or CSV.

Compatibility with FANUC CNCs

The operating state of machines equipped with FANUC CNCs can be sorted into detailed categories to identify the cause of stops or the contents of alarms.

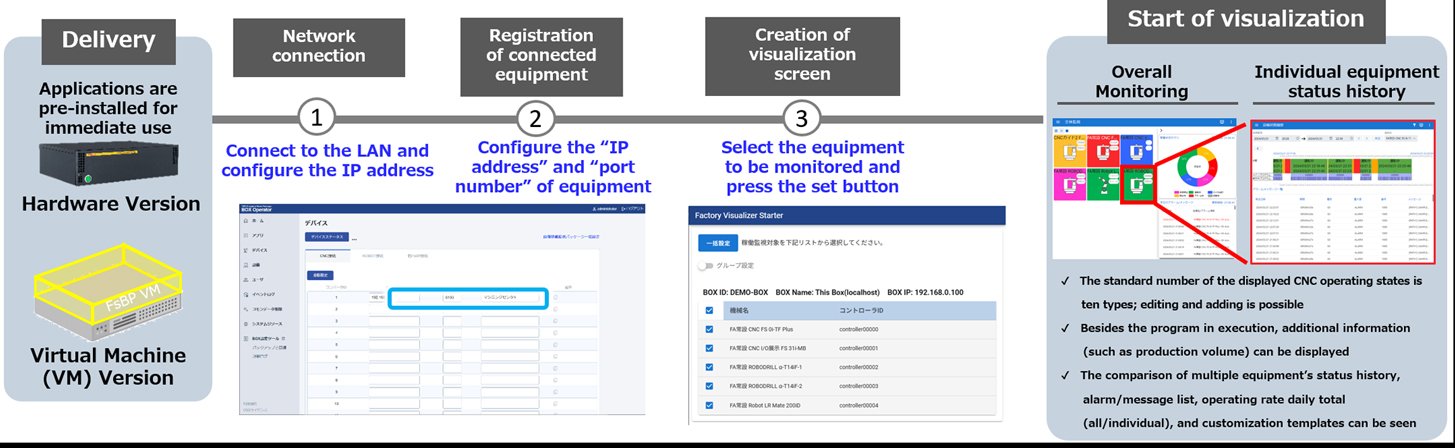

1.Easily Collects and Visualizes Data from Equipment

- Required applications are all pre-installed; on-premise operation is possible

- With just three steps, collection begins of equipment data that can be used immediately for improving operation

- By simply selecting the equipment, the operation monitoring screen is automatically generated

- Six types of standard screens can readily be used to visualize equipment status

* The connection procedure for equipment fitted with non-FANUC CNCs or other company’s equipment may differ according to the supported protocol.

2.Collects Data from Other Manufacturer’s Equipment

- Can collect data from other manufacturer’s equipment as well, so that data can be used without being concerned about the difference in manufacturer.

New Functions of FIELD system Basic Package

- The servo data analysis application can now be used with the collection of FANUC CNC servo data. Thus, the waveforms of servo data can be visualized and analyzed.

- FANUC CNC program transfer and the reading/writing of CNC macro variables is now possible, making FANUC CNCs more convenient and flexible to use.

- Modbus TCP, which is utilized extensively in factory equipment is now supported. This allows for the collection of data and the control of equipment that uses Modbus TCP.

- FIELD system Basic Package now supports integration with FANUC CNCs optional Machine Status Monitoring Function (Visual Assist). By correlating the machine’s operation history or operating data at the time of the alarm, with the video recordings, anomalies can be analyzed.

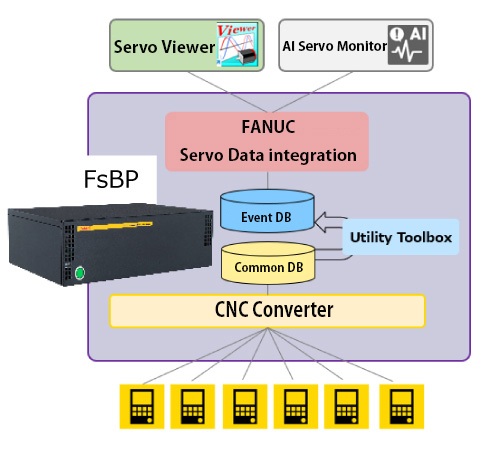

Coordination with Servo Data

Overview

- Data platform for providing servo data to AI Servo Monitor and Servo Viewer

Effects

- AI Servo Monitor uses the servo data collected by FsBP (FIELD system Basic Package) to detect signs of machine failure

- Servo Viewer can download the servo data obtained by this application to draw graphs of the data or analyze the data

- Centrally manages servo data of multiple CNCs, and can also manage this data in correlation to other data acquired by FsBP (such as work ID and executed program name)

CNC Program Transfer, Macro Variable API

Overview

- CNC File Transfer API

- CNC macro variable read/write API (Extension API)

Effect

- Only accounts authorized by the administrator can execute the following:

- CNC File Transfer API

- Macro variable read/write API

- More seamless data sharing between FsBP and other systems such as file management and production management systems

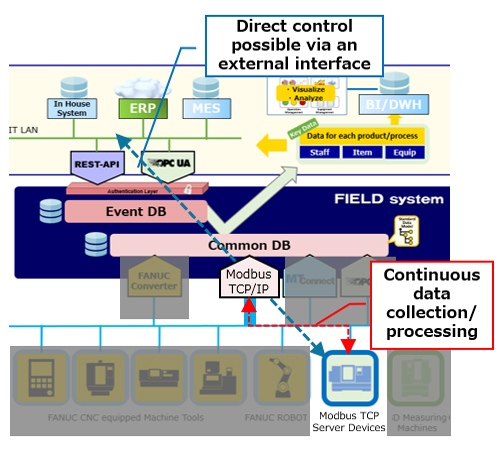

Supports Modbus TCP

Overview

- Can connect to Modbus TCP server devices (slave)

Effect

- Data is continuously collected from Modbus TCP-compatible devices

- The collected data is recorded and aggregated in chronological order, and made available for external use

- Modbus TCP-compatible devices are directly controlled via external interfaces

- Arbitrary addresses can be read or written from MES using OPC UA

- Arbitrary addresses can be read and written from internal systems via HTTPS

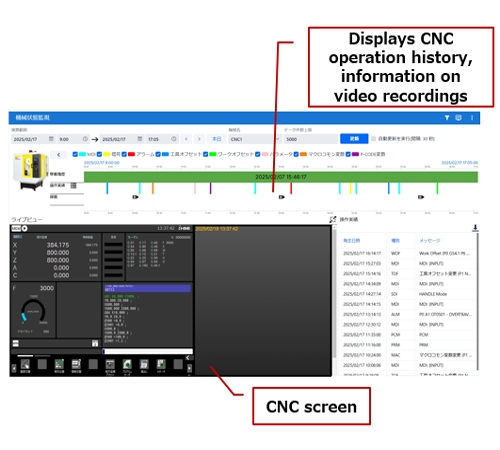

Use with Machine Status Monitoring (Visual Assist)

Overview

- Can be used with the optional Machine Status Monitoring (Visual Assist) Function of FANUC CNC

- Live views, display of operation history, and video playbacks are possible on the Factory Visualizer screen

Effect

- The status of multiple machines are centrally managed by Factory Visualizer, thus improving monitoring precision

- Data collected by the Machine Status Monitoring (Visual Assist) Function can be used externally by utilizing the API of FsBP

FIELD system Basic Package Product Description and Main Specification

- FIELD system Basic Package comes in two versions: a hardware version that is ready for immediate use, and a virtual machine (VM) version which can be installed in a customer’s server. They can be selected according to the customer’s environment.

FIELD system Basic Package Hardware Version

FIELD BASE Pro - Main specifications (maximum of 50 machines can be connected)

| Item | Specifications |

|---|---|

| CPU | Intel Xeon processor with 4 cores |

| Memory | 16GB |

| Storage | SSD 960 GB |

| Dimension | Width 382 mm x Depth 281 mm x Height 103 mm |

| Weight | Approximately 6 kg |

| Power consumption | Maximum 100 w |

| Ambient temperature | 0~45℃ (operating) -20~60℃ (idle) |

| Ambient relative humidity | 75%RH or less (No condensation allowed) |

| Installation criteria | Pollution Degree 2 (example: offices) |

FIELD system Basic Package Virtual Machine (VM) version

Virtual Machine - Recommended requirements (when connecting 50 machines)

| Item | Specifications |

|---|---|

| Hypervisor | VMware ESXi |

| CPU | Intel Xeon-equivalent CPU with minimum 4 virtual cores |

| Memory | 16 GB or more |

| Storage | SSD 1TB or more |

FIELD system Basic Package Software - Main Specifications

| Item | Specifications |

|---|---|

| Connectable devices (FANUC) | FANUC CNC: (Ethernet connection required. Contact us for details.) FANUC Series 16i/18i/21i/30i/0i-B or later models, FANUC Power Motion i-A FANUC ROBOT: (Contact us for details) R-30iB/R-30iB Mini/Mate controller |

| Example of data collectable from FANUC products | CNC machine tool: Name of program in execution, production volume, G/M/T code in execution, spindle speed and load, alarm, macro variable, PMC signal, servo data, others ROBOT: Name of program in execution, production volume, cycle time, alarm, torque, current, axis position, register value, I/O value, others |

| Connectable devices (Non-FANUC) | CNC machine tool, ROBOT or PLC which support OPC UA or MTConnect connection PLC and equipment that support Modbus TCP connection |

| Minimum data collection cycle | 1 ms (FANUC CNC servo data), 100 ms (FANUC ROBOT), 500 ms (other than left) |

| Supported data input format | MTConnect, OPC UA (supporting UA4MT/umati and EUROMAP 77/83), Modbus TCP, REST-API (HTTPS) |

| Supported data output format | OPC UA (supporting UA4MT/umati MachineTool Basic Server Profile), CSV file export, REST-API (HTTPS) |

| Number of units that can be connected | 5, 10, 20, 50, 100 units (software annual subscription licenses to be purchased separately; connecting 100 units is only feasible with the VM version) |

| Data integration condition | Software which supports REST-API such as spreadsheet software, BI tool, MES, ERP, or OPC UA |

(July 2025)