Materiality

FANUC, which has continuously pursued Factory Automation (FA), commands an exceptionally high market shares for CNC systems and industrial robots. FANUC products of FA, ROBOT, and ROBOMACHINE businesses are used at factories throughout the world. Any interruption in the supply of such products would thus lead to stoppages at customers’ factories. Furthermore, as the Company’s products also contribute to the decarbonization of and productivity improvements at customers’ factories, they have an important and extensive impact on the environment and society.

With its customer-oriented products, FANUC is shaping the future of the manufacturing industry.

If FANUC is to achieve sustainable growth under its basic principles of “Strict Preciseness” and “Transparency,” it must create both social and economic value and conduct long-term management without focusing solely on short-term gains. Doing so will require us to solve social issues through our businesses in order to contribute to a sustainable society.

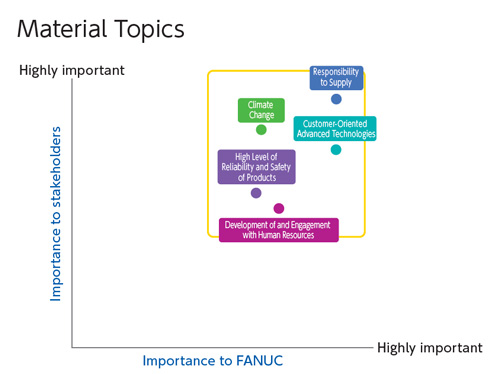

In this light, we have revised our materiality based on our belief that their resolution is important for such management to be successful.

Process for Identifying Materiality

STEP1 Clarification of Issues

FANUC determined social and customer needs and clarified sustainability-related issues with reference to global disclosure standards,*ESG rating agencies, and industry trends.

*ISO 26000, SDGs, GRI Standards, and SASB Standards

STEP2 Examination of the Importance of Issues

The Sustainability Committee, which is chaired by the Representative Director, President and CEO and composed of members tasked with spearheading management, such as the Chairman and the general managers of each business division, evaluated each of the issues clarified and classified. Through questionnaires and individual interviews, all committee members evaluated said issues in terms of their importance to FANUC and their importance to stakeholders. The committee also reflected in its evaluations objective opinions obtained through dialogues with outside experts and investors.

STEP3 Identification of Materiality

The Company narrowed down issues through discussions by the Sustainability Committee. Thereafter, taking into account the opinions of outside directors, we identified our Materiality following deliberations at a meeting of the Board of Directors.

STEP4 Future Actions

FANUC will promote initiatives in relation to its Materiality and raise awareness thereof Companywide. Moreover, with the Sustainability Committee taking the lead in periodically revising the Materiality and with the Board of Directors deliberating and monitoring them, we will promote management based on our Materiality.

Materiality

Responsibility to Supply:Building and maintaining long-term relationships of trust with customers

・Why the Issue is Material

Fulfilling our responsibility to supply is of the utmost importance for maintaining relationships of trust with customers. As any interruptions in supply from FANUC would lead to stoppages at customers’ factories, we take such responsibility extremely seriously. A strength of the Company is its continuous operation of a maintenance service system for customers, while its ability to stably supply products and services enables FANUC to offer added value. Fulfilling our responsibility and continuing to exist as a company needed by society are crucial.

・Ideal state

As a supplier of capital goods, FANUC will anticipate a wide range of scenarios, including natural disasters and geopolitical risks faced by the Company and its suppliers. Mindful of such scenarios, we will supply products in a stable manner and continuously operate a sophisticated maintenance service system in accordance with global standards while paying close attention to environmental and social trends. In this way, we will contribute to improving the uptime of factories around the world.

Customer-Oriented Advanced Technologies:Anticipating and creating customer needs

・Why the Issue is Material

Pursuing a customer-oriented approach has been and will remain a key value in FANUC’s stance. Our ability to promptly provide feedback on our research and development efforts by using our products at companyowned factories serves as a strength. Anticipating customer needs based on such information enables FANUC to enhance customer satisfaction while helping it maintain and improve product competitiveness and shape the future of the manufacturing industry. Maintaining our industry-leading position by offering highly advanced products that are based on innovative technologies and which underpin production floors is thus vital.

・Ideal state

FANUC will firmly grasp customer needs by rigorously ensuring that it constantly pursues a customeroriented approach. Through the development and popularization of advanced technologies, we will continuously improve customer satisfaction and shape the future of the manufacturing industry by developing products that anticipate customer needs and the changing times.

Climate Change:Contributing to climate change mitigation

・Why the Issue is Material

Greenhouse gas emissions associated with the use of its products at customers’ factories far outweigh such emissions resulting from FANUC’s business activities. Accordingly, there is an increasing need among customers and in society for energy-saving products, making it essential that we contribute to efforts in relation to carbon neutrality. FANUC can curb the energy consumption of its customers by improving the productivity of factories around the world through highly energy-efficient products arising from innovation.

・Ideal state

Viewing climate change as both a risk and an opportunity, FANUC will promote the development of highquality, environment-friendly products, including those that realize energy-savings and high levels of energy efficiency. Doing so will allow us to contribute to the achievement of carbon neutrality and a sustainable society.

High Level of Reliability and Safety of Products:Maximizing Uptime in customers’ sites

・Why the Issue is Material

FANUC’s product development is centered on the principle of “Reliable, Predictable, Easy to Repair.” The high level of reliability realized by the durability of such products helps improve productivity at factories, thereby raising the competitiveness of FANUC as well as of its customers. In addition, FANUC’s products are vital in that they not only protect those operating them from physical hazards but also boast a high level of cyber security.

・Ideal state

FANUC will maintain and improve the high quality of its products and offer extensive maintenance services to improve the uptime of customers’ factories. We will also aim to realize safe and secure production sites.

Development of and Engagement with Human Resources:Cultivating human resources to lead the future of the manufacturing industry

・Why the Issue is Material

Outstanding human resources are the driver of corporate activities, making them indispensable to the sustainability and innovation of companies. Efforts to develop human resources must thus be reinforced from a medium- to long-term perspective, requiring proactive and continuous efforts that lead to improved motivation.

・Ideal state

Given that human resources are of the utmost importance for ensuring growth over the medium- to longterm, FANUC will strive to enhance its conditions for developing human resources and further improve their motivation. We will attract and secure outstanding human resources and seek to establish an organizational culture and environment conducive to cultivating and enhancing human resources who will lead the future of the manufacturing industry.