ROBOMACHINE Business

- Products

- ROBODRILLs (compact machining centers)

- ROBOSHOTs (electric injection molding machines)

- ROBOCUTs (wire electrical-discharge machine)

- Strengths

- Products applied with CNCs and servos, FANUC's basic products

- Top-level global market share of ROBODRILLs (compact machining centers) (FANUC estimate)

- Top-level global market share of ROBOSHOTs (electric injection molding machines) (FANUC estimate)

- High performance, high operating rates, easy to use

Business Overview

Products of the ROBOMACHINE business are comprised of machine tools or industrial machinery installed with FANUC's CNCs and servos. They are used for production in factories of customers. They are all highly compatible with FANUC robots. Factory automation is enhanced through the combination of ROBOMACHINEs and robots.

Customers can improve quality of their products and shorten the time it takes for machining by using FANUC's highly reliable, high-performance ROBOMACHINE products. The products will contribute to improved productivity of customers' factories.

Furthermore, a function to monitor the operational status of the entire factory in real time will enable designing of more precise production plans and improvement in operating rates (FIELD system Basic Package, ROBOSHOT-LINKi2, and ROBOCUT-LINKi).

Furthermore, ROBODRILLs, ROBOSHOTs, and ROBOCUTs became eligible for a subsidy for business expenses supporting promotion of advanced energy-saving investments and demand structure transformation allocated in the FY2024 supplementary budgets. They are also eligible for a subsidy in FY2025 for ESG lease promotion business for the establishment of a decarbonized society.

Value Created by ROBODRILLs

ROBODRILLs are compact machining centers. They are used for machining metal materials, such as iron and aluminum, with tools and for drilling holes.

The products have superior machining performance for their compactness and contribute to making production equipment smaller and saving energy. They improve production efficiency by thoroughly reducing redundancy in machines' operation, and achieve more stable machining through the use of thermal displacement compensation function. These features help improve machine customers' product quality and productivity.

Value Created by ROBOSHOTs

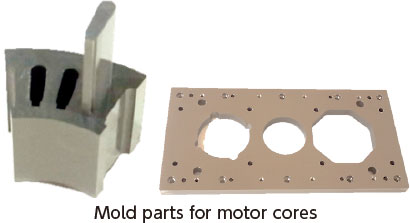

ROBOSHOTs are electric injection molding machines. They form melted plastics, etc. into shapes by casting them into metal molds. Many components used in daily lives, including mobile phone components, auto parts, and medical instruments, are made using injection molding machines.

FANUC's products can perform more precise and stable molding thanks to the highly-rigid and low-friction mechanism and the use of our excellent CNC and servo technology, and contribute to manufacturing of high value-added precision molded products. AI backflow monitor helps estimate the amount of wear on backflow prevention rings, allowing for replacement of components at optimum timing. This contributes to reducing molding defects and improving operating rates.

Value Created by ROBOCUTs

ROBOCUTs are wire electrical-discharge machine, which use discharge phenomena between wire electrodes and the workpiece to perform machining. They can perform machining on anything from thin boards to ultrahard materials, which are difficult to process for cutting tools, into complex shapes as long as the material is conductive, regardless of its hardness.

By achieving stable machining through the use of the AI thermal displacement compensation function, these products contribute to improving customers' product quality. The highly reliable automatic wire feeding function (AWF3) can automatically recover feeding when a wire is accidentally cut and disconnected during machining, thereby enabling unmanned operation for long periods. These features contribute to improving operating rates.

TOPIC

In the latest model of the ROBOSHOT α-SiB Series, we have introduced a 21.5-inch-wide display screen (PANEL iH Pro), the largest of its kind in the industry, which enables simultaneous display via a unique divided screen, offering both superior operability and visibility. Furthermore, we have adopted a fully enclosed cover style for the injection unit, which is the only one of its kind in the industry, realizing safety, operability, and maintainability. In recognition of these innovations, we received the “51st Industrial Machinery Design Award IDEA: The Japan Society of Industrial Machinery Manufacturers (JSIM) Award.”