FA New Functions: Tool Management Function (FANUC Series 500i-A)

With the Tool Management Function, various data of tools used by machine tools can be managed centrally. The data is used in a wide range of commands such as those for compensation in machining programs, tool change, as well as commands to specify the feed rate and spindle speed.

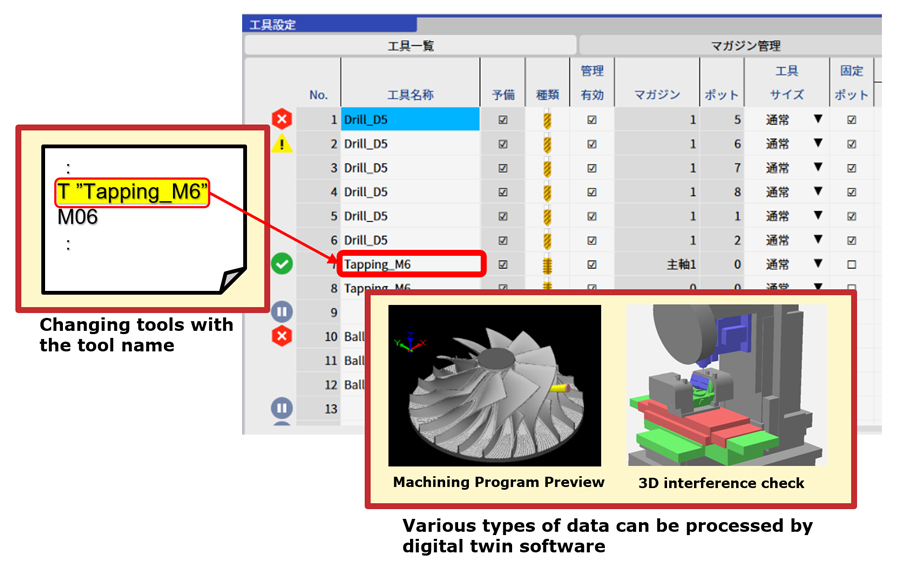

The Tool Management Function has been greatly enhanced in the FANUC Series 500i-A. Each tool can be named so that a tool can be selected by specifying its name from the machining program. By using the tool name instead of the tool number, on-site management becomes intuitive and easy-to-understand.

The offset value of the tool that is selected by the tool change command is automatically applied. This facilitates the creation of machining programs and prevents errors caused by the application of incorrect offset values.

In addition, after a tool change, tool length compensation automatically starts, eliminating the need to include a compensation command in the machining program. Such automatic compensation significantly reduces machining defects and the risk of collision between the workpiece and the tool.

The specifications allow designs to be simplified without sacrificing the flexibility of the interface with machine-side operations, thus reducing the design workload for machine manufacturers.

The data and mounting position of each tool can be managed with the dedicated tool management screen, which offers a simple and user-friendly interface.

Furthermore, various tool-related data can be shared with a digital twin environment, and processed by a broad range of digital twin software.

(July 2025)