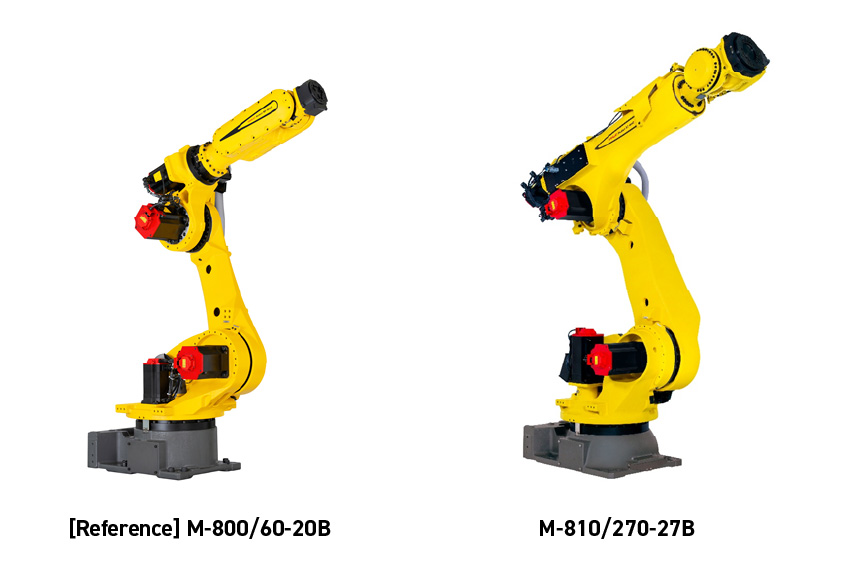

ROBOT New product: Machining Robot M-810

In recent years, the demand for machining using six-axis articulated robots has been increasing due to the growing size of automotive components, such as giga casting.

To meet the demand, FANUC has included the M-800 robot in its product lineup and has newly developed and started the sales of the M-810, which offers a 1.3 times larger operating space and supports 3.4 times higher machining load compared to the previous model M-800.

Features of the Robot

High machining load

- Thanks to a high-rigidity arm, high-precision calibration for accurate path control, and unique technology to maintain tool path even under machining reaction forces during operation, the robot is applicable to high machining load.

- It is also capable of milling, drilling, and tapping on steel workpieces that require higher performance than the M-800.

High environmental performance

- The entire robot features IP67-compliant environmental protection.

- It is compatible not only with dry machining, where chips are dispersed, but also with wet machining using cutting fluids.

High flexibility

- In cases where the workpieces are too large to be set in a standard machining tool and the process is primary machining or drilling, a robot machining system can be installed in a compact layout, also offering advantages in terms of cost-effectiveness.

- Utilizing the flexibility of a six-axis articulated robot, it is also possible to approach the workpiece from various directions.

This robot was displayed in use in a real application at FANUC’s New Products Open House Show in May 2025.

Shipment start: June 2025 (M-810/270-27B)

(August 2025)