ROBOT New Technology: Open Platforms & Physical AI

Accelerating Physical AI Implementation through Open Platforms

FANUC is strongly supporting open platforms to accelerate automation, by applying AI advancements to robots. As part of this initiative, we are pleased to announce that we have released a dedicated driver for controlling FANUC robots on the open-source robotic development platform “ROS 2,” as open-source software on GitHub, the world’s largest development platform for storing, sharing, and managing source code. Our robots also support “Python”, a programming language widely used in AI development, as standard, making them ideal for implementing Physical AI on open platforms.

One of the advantages of an open platform is the ability to flexibly utilize computing resources from cloud (data centers) and edge servers connected via next-generation high-speed communication.

Many companies, startups, universities and research institutions are exploring Physical AI using ROS and Python. Supporting an open platform by making the ROS 2 driver source code for FANUC robots public, allowing Python execution, and enabling high-speed external command input, facilitates the introduction of Physical AI combined highly reliable FANUC robots, ranging from small robots with a payload of 3 kg to large robots up to 2.3 tons, and the latest AI technologies to manufacturing sites.

Many companies, startups, universities and research institutions are exploring Physical AI using ROS and Python. Supporting an open platform by making the ROS 2 driver source code for FANUC robots public, allowing Python execution, and enabling high-speed external command input, facilitates the introduction of Physical AI combined highly reliable FANUC robots, ranging from small robots with a payload of 3 kg to large robots up to 2.3 tons, and the latest AI technologies to manufacturing sites.

At the International Robot Exhibition to be held this December, FANUC will display real-world examples of Physical AI applications implemented on an open platform for the very first time. Visitors will be able to see, touch, and talk to FANUC robot systems which actually move, directly experiencing how the latest AI technologies can be utilized on the factory floor.

Key Features of the FANUC ROS 2 Driver

- Compatible with the ros2_control framework, making high-precision, real-time motion control possible.

- Supports ultra-high-speed control at 1ms, among the highest standards in the industry.

- In addition to FANUC’s CRX series collaborative robots, FANUC robots, ranging from small robots with a payload of 3 kg to large robots up to 2.3 tons, can be connected through the ROS 2 driver.

Source code available on GitHub

AI Robot Recognizes Your Voice Commands

AI Robot that Avoids People

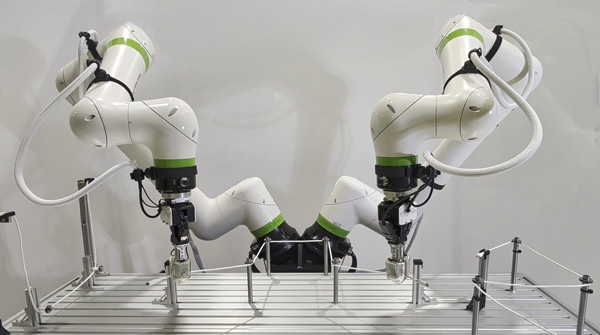

Two Arms Install a Flexible Cable

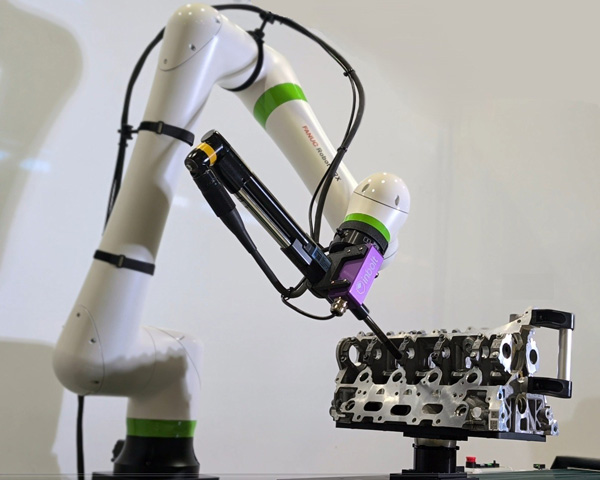

AI Robot Tracks Moving Parts, and Tightens Screws

Advancing Physical AI and Digital Twins Through Collaboration with NVIDIA

FANUC is collaborating with NVIDIA to advance the implementation of Physical AI in industrial robots. Moreover, FANUC robots will realize a digital twin in a photorealistic virtual factory by NVIDIA Isaac Sim, an open-source, reference robotic simulation framework built on NVIDIA Omniverse libraries, for simulation.

- In the aforementioned physical AI applications by FANUC robots, the NVIDIA Jetson on-robot computer and NVIDIA AI infrastructure are utilized. Experience the synergistic effect of the NVIDIA AI platform combined with FANUC's industrial robots at the International Robot Exhibition venue.

- In addition to the FANUC Collaborative Robot CRX series, FANUC robots ranging from small robots with a payload of 3kg to large robots up to 2,3 tons will be available as OpenUSD SimReady assets in Isaac Sim. Robot application developers can freely place FANUC robots in realistic virtual factories powered by Omniverse libraries, efficiently acquiring and generating AI learning data, performing accurate simulations, and conducting production operation tests.

- By integrating FANUC's robot simulation software ROBOGUIDE with NVIDIA Isaac Sim, it is possible to perfectly reproduce the real robot operation with accurate trajectories and cycle times using the same algorithms as the actual robot. At the venue of the International Robot Exhibition, you will be able to see FANUC robots in operation in a photorealistic virtual factory.

Photorealistic Virtual Factory by NVIDIA Isaac Sim and FANUC ROBOGUIDE

(December 2025)