Safety and Quality

Promotion system for ensuring product quality that can be used with confidence

The quality includes various factors, such as safety, compliance, reliability, security, and design.

FANUC promotes quality improvement activities throughout the entire process, starting from product development and design to product quality refinement and service after manufacture and shipment, with a focus on enhancing product quality.

To ensure product safety, we comply with various safety standards. In addition, we are conducting risk assessments, including hazard identification, risk assessment, risk reduction, and verification of effectiveness during the design phase.

Additionally, in the event of a malfunction, we conduct risk assessments based on the severity of harm and frequency of occurrence, evaluate the level of risk, and determine the appropriate corrective actions.

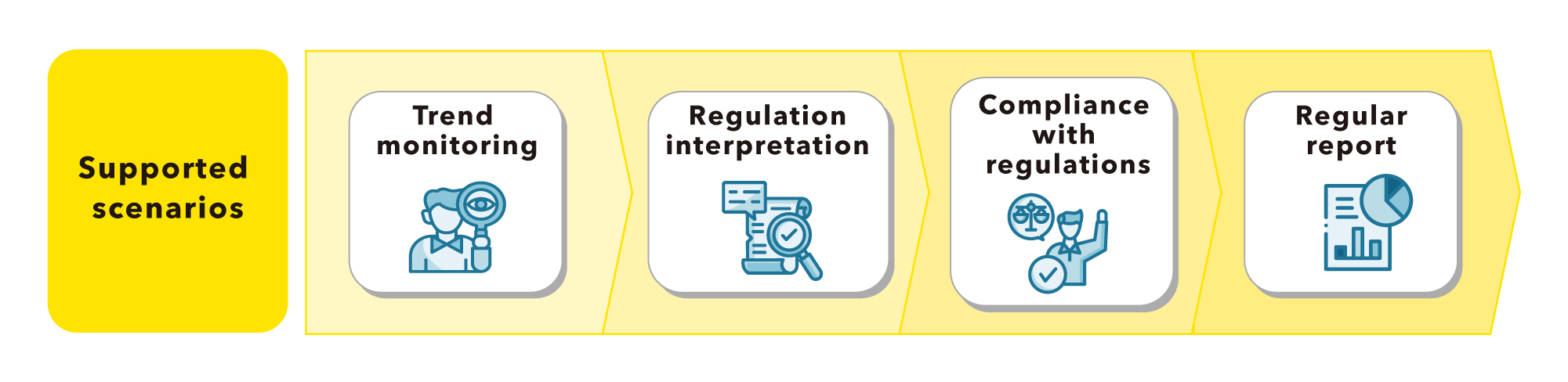

For compliance, we monitor trends in laws and regulations relevant to each product and verify conformity, with cooperation across multiple departments.

Product reliability is built into the development process from the development stage, with verification and validation, including reviews and reliability assessments, incorporated into the development process.

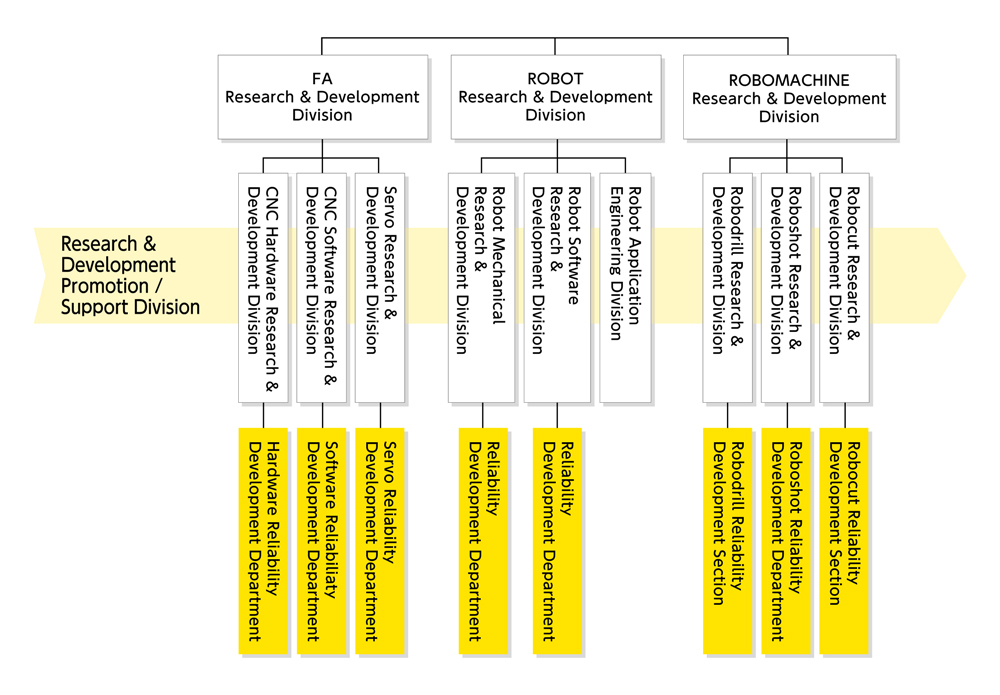

We have established our system where the Research and Development Division is responsible for ensuring high reliability to ensure the swift resolution of issues and prevent recurrence.

We have established a Quality Management Division to independently oversee and ensure that these activities, especially compliance and reliability enhancement, are effectively implemented across all our products. The Quality Management Division is composed of the Corporate Quality Management Department, responsible for cross-functional deployment and promotion across all products, as well as the FA Quality Management Department, ROBOT Quality Management Department, and ROBOMACHINE Quality Management Department, each responsible for respective product lines.

To ensure compliance with laws and regulations, the Quality Management Division focuses on collecting the latest information, establishing internal rules based on laws and regulations, overseeing and auditing tests to confirm compliance, and conducting awareness campaigns and educational programs to deepen the understanding of responsible personnel.

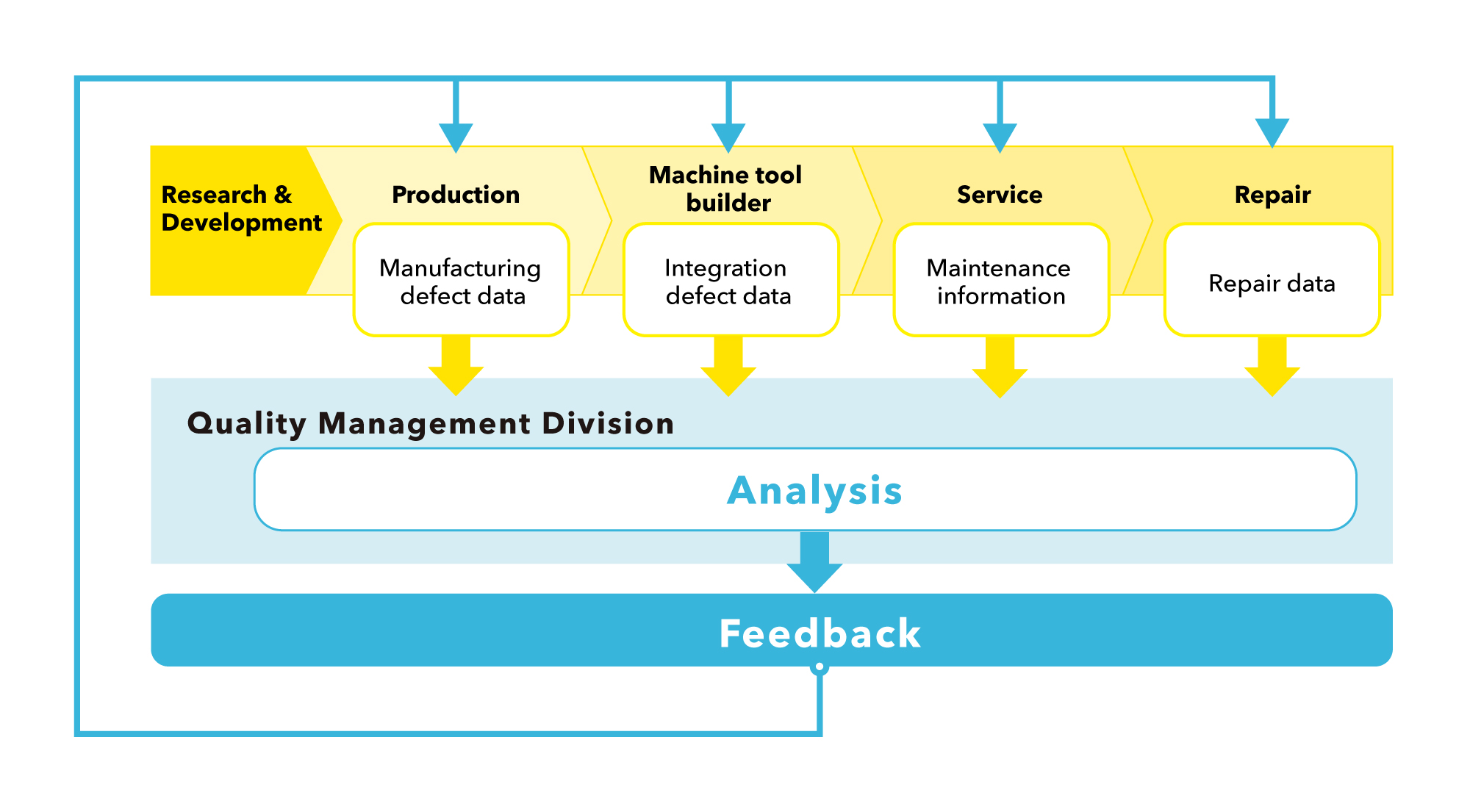

For reliability improvement, we are working on the analysis of product quality data, collection, and sharing of lessons learned and insights.

We share information on quality, technology, security, and other areas, and work to improve quality through various regular meetings, not only within each division but also across divisions.

FANUC continue the following activities, aiming at the improvement of product quality.

- Technical meetings (Held for executives of the Research & Development Division)

- Quality Improvement Meeting (Held for the Research & Development Division)

- Reliability Meeting (Held at each Research & Development Division)

- Quality meeting (held in the Production Division and Research & Development Division to improve production quality)

- Reliability Study Session (Held for people in charge of Research & Development)

- ISO9001, Education on Laws and Standards (Held for people in charge of Research & Development and Production)

ISO9001

FANUC strives to ensure customer satisfaction, compliance with laws and regulations, and the safety and quality of its products through a quality management system based on ISO9001. We also review and evaluate the results of quality management system activities, and plan and implement internal quality audits to verify conformity with ISO9001, assess effectiveness, and make improvements.

| Domestic | 100% |

| Overseas | 100% |

Internal Quality Audit

For Internal quality audit, independence and impartiality are crucial. To strengthen this point, we have established a Quality Management Division independent of Research & Development and Production Division, whose members serve as auditors to conduct the internal quality audits. The Quality Management Division assesses compliance with laws and regulations, identifies quality fraud and issues that could lead to quality fraud, considers improvement measures, and evaluates the effectiveness of internal quality audits. The results of these reviews are reported to the Representative Director, President and CEO, as well as the relevant divisions. In the relevant divisions, improvement proposals are proactively reviewed and initiatives such as revising rules are advanced, based not only on instructions from the Representative Director, President and CEO, but also on information provided by the Quality Management Division.

Compliance with laws and regulations

In each country and region, there are various laws and regulations regarding products to ensure the safety of customers and local communities, as well as environmental protection. We are working to ensure compliance with the laws and regulations of each country for all products, including CNC systems integrated into machines. Information about laws and regulations is collected and organized by the Corporate Quality Management Division, and after being interpreted by the Quality Management Departments of FA, ROBOT, and ROBOMACHINE products, it is disseminated to each Research and Development Division. In each Research & Development Division, compliance management is carried out, while the Corporate Quality Management Division verifies the regulatory compliance status of each product and disseminates this information company-wide.

“Visualization” of Quality and Reliability

The status of quality and reliability in all processes, from product design to manufacturing and after-sales services, is monitored in order to promptly respond to defects. We collect data from our after-sales services, analyze it, identify issues, and give feedback to our production divisions and Research & Development Divisions. These activities improve our products’ quality and reliability.

Reliability Development Technology

We promote the creation of systems to design and manufacture highly reliable products, as well as the sharing of insights to enhance the reliability development capabilities of people in charge of Research and Development. The Quality Management Division regularly reviews methods for addressing reliability issues and promotes the standardization of reliability development practices. In product development, we have formalized the procedure as the “Product Development Guidelines” to incorporate reliability from the development stage while meeting various requirements.

We have established the "Troubleshooting Procedure" for addressing malfunctions and the "Incident and Vulnerability Response Guidelines" to promptly respond to security incidents and vulnerabilities in our products.

For malfunctions and vulnerabilities, we use a centralized management system to track the entire process, from identifying the causes to implementing countermeasures, and visualize the progress to prevent any omissions in the response. Insights and lessons learned from the management system are utilized company-wide, proving effective in quality integration, quality improvement measures, defect prevention, recurrence prevention, and the training of young engineers. Furthermore, we have established a "Learning from Malfunctions Corner" in the Reliability Evaluation Building, where actual defective products are displayed, and use it as a teaching tool to educate people in charge of Research and Development.

Learning from Malfunctions Corner

Reliability Evaluation Technology

As FANUC products are used in manufacturing sites, they are exposed to extremely harsh environments. In order to ensure that our products can operate stably for long periods of time under these conditions, while contributing to minimizing downtime in our customers' factories, we are promoting the standardization of evaluation tests by conducting them in a variety of surroundings.

The Reliability Evaluation Building, which opened in 2016, has a total floor area of approximately 22,679 square meters (103 meters wide × 198 meters deep), and houses a variety of equipment for thorough reliability verification.

This facility is equipped with dedicated test rooms, such as an anechoic chamber, an EMS (electromagnetic susceptibility) test room, a vibration test room, a mist test room, a variable temperature room, a variable humidity room, a capability limit test room, a noise measurement room, a submergence test room, a clean room, and a precision measurement room. In this facility, a variety of tests are performed while taking into account variations in data under various conditions, including the accelerated life test to evaluate long-term reliability.

Reliability Evaluation Building

Anechoic chamber

Mist test room

Ensuring Customer Safety

FANUC prioritizes operator safety above all else and enhance product safety to contribute to improving safety and operation rate at our customers' factories.

We are engaged in research and development to achieve a higher level of safety, FA, ROBOT, and ROBOMACHINE products comply with the safety standards of each country.

| Complying with safety standards | We fully meet safety standards, such as ISO and IEC, and have been certified by certification bodies. The ROBOSHOT α-SiB series meets the newly established safety requirements for injection molding machines (ISO20430, JIS B 6711). This will ensure the safety of operators and molding worksites in accordance with the new safety standards. |

|---|---|

| Dual Check Safety (DCS) | The CNC complies with safety standards (IEC61508 SIL 3*, IEC62061 maximum SIL 3*, ISO13849-1 PLe*) and has been certified by certification bodies. (*SIL 2, PL d applies if spindle motor is included.) Safety-related signals are duplicated for comparative monitoring. In the event of a failure in one hardware safety circuit, the other detects the failure, thus maintaining the safety of the system. ROBOT features a safety-certified emergency stop function PL e, Cat4 (ISO13849-1)、SIL3 (IEC61508), and a safety-certified position/speed check function PL d, Cat3, SIL2. It ensures high safety levels—such as monitoring the robot's operational area and safety speed—using only standard servo motor sensors, without the need for additional hardware. |

| Malfunction prevention function | The design gives consideration to safety, such as by halting and issuing an alarm in the case of accidental operations by the operator. In the future, we will work on a feature that stops functions pertaining to hazardous and accidental operations, as well as one that prevents such choices. |

| Collaborative robots | Collaborative robots do not require a safety fence, because they securely stop operating when coming into contact with humans. These robots are used to assist in tasks alongside human workers, enabling operators to avoid heavy lifting, so that persons with less physical strength can perform tasks safely. |

| Smooth stop function | This function stops robots on a procedure that has been confirmed to be safe in the shortest possible time, in case of any abnormality. |

| Brake error diagnosis function | If a failure occurs on a brake while the robot is in operation or at rest, the power of the brake may decrease, causing the robot's gravity axis to fall. This function provides early diagnoses of such brake malfunction, and notifies the user in advance. |

| Cyber security support | The latest robot controller R-50iA, which is the world's first robot controller (according to our research) to have obtained international cyber security certification (IEC62443-1, IEC62443-2). It blocks cyber-attacks from external sources, allowing you to build a reliable robot system. 500i-A series CNC has obtained international cybersecurity certifications (IEC 62443-4-1/2), ensuring safe connectivity to the network within the manufacturing site. |

| Remote Control | We have developed a remote operation function using two robots: a human operator directly controls the leader robot, while a follower robot faithfully replicates its movements to perform tasks in dangerous locations. The force exerted by the workpiece detected by the follower robot is transmitted to the leader robot, allowing the operator to manipulate it as if feeling the force directly at their fingertips. It enables the safe execution of hazardous tasks requiring subtle adjustments of force, such as grinding operations and slag removal of hot molten metal in casting. |

| Custom Programmable Machine Controller (PMC) safety function | In our ROBODRILL, the customer or system integrator can apply the abovementioned DCS to the control of peripheral equipment that is additionally installed on the ROBODRILL. This will make the separate safety circuits and control equipment unnecessary. |

| Fully covered structure for injection units | The ROBOSHOT injection unit is fully covered to prevent accidental contact with the hot injection unit, which is heated by the heater. |

Product Design

In line with our “Simple & Smart” design policy and the human-centered design (HCD) concept, we create products that fulfill our users’ requirements and greatly satisfy them, without being deficient or excessive. While complying with ISO, JIS, and local laws and regulations, we aim for designs that seriously take into consideration user-friendliness and safety. We are in the process of formulating related guidelines. Our new collaborative robot CRX, released in December 2019, gives the rough, rugged image of industrial robots a fresh new look. The clean, rounded lines of this novel design offer a soft external appearance that allows the operator to share space with the CRX comfortably.